Every stage of industrial production is closely linked to water quality. This is because it directly affects not only the quality of end products but also the lifespan of production equipment.

In recent years, traditional water treatment methods have become increasingly inadequate for the demands of high-precision purification. Instead, ultrafiltration water treatment machine, with its outstanding advantages of high efficiency and stability, has gradually become the preferred solution in the industrial water treatment field.

What ultrafiltration water treatment membrane should we use?

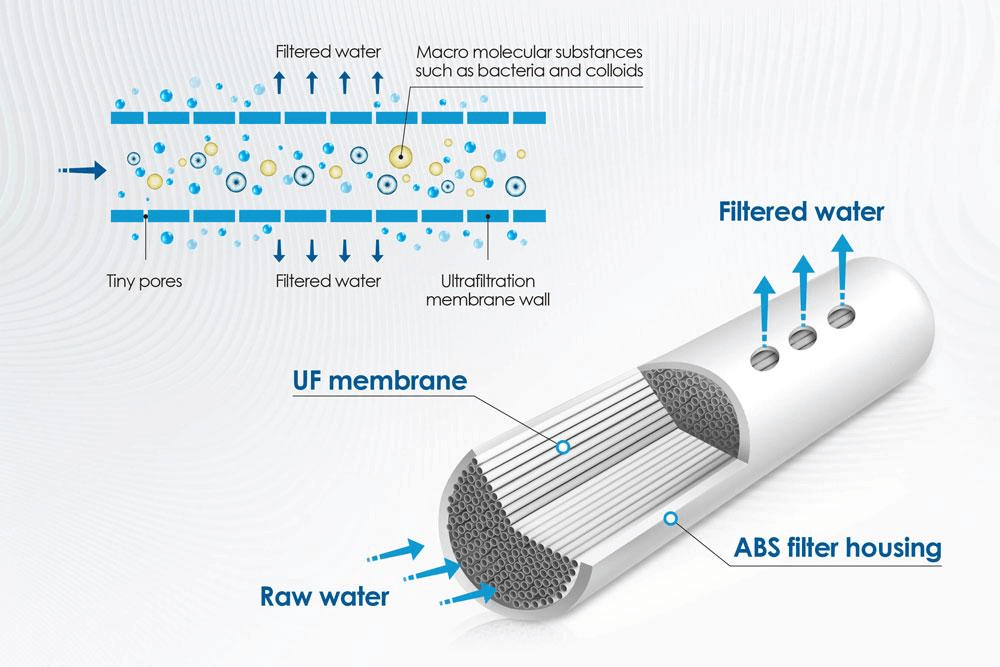

Ultrafiltration water treatment relies on the precise sieving characteristics of polymer membranes. Under moderate pressure, water molecules and small organic molecules can pass through the membrane pores smoothly, while the membrane traps colloidal particles, suspended impurities, microorganisms and macromolecular pollutants in the water on its surface.

Compared to traditional filtration processes, ultrafiltration membranes have pore sizes ranging from 0.01 to 0.1 micrometers. A precision is difficult for traditional methods such as quartz sand filtration and activated carbon adsorption to achieve. Therefore, they can remove over 99% of turbidity and pathogenic microorganisms from water. And the entire process requires no chemical additives, fundamentally eliminating the risk of secondary pollution.

What are the advantages compared to traditional methods?

In industrial applications, the value of ultrafiltration technology is particularly evident.

On the one hand, it possesses strong adaptability to various scenarios. Engineers can flexibly adjust membrane materials and operating parameters according to the water quality characteristics of different industries. Whether it’s high-purity water preparation in the electronics industry, water purification in food processing, or wastewater recycling in the chemical industry, it can provide customized solutions.

On the other hand, its operational economy is outstanding. The ultrafiltration membrane adopts a cross-flow filtration design, which effectively reduces membrane fouling and extends the membrane’s service life. Simultaneously, the equipment has a high level of automation, requiring only a small number of maintenance personnel to ensure continuous and stable operation. Furthermore, it offers significant environmental benefits. For example, we can recycle industrial wastewater after ultrafiltration treatment, greatly reducing the company’s fresh water consumption and thus achieving water conservation and emission reduction targets.

What upgrades have been made to ultrafiltration water treatment tech?

Based on 15 years of experience in water treatment equipment manufacturing, we have upgraded our ultrafiltration systems in multiple dimensions to address the pain points of industrial water treatment. For example, in membrane module selection, we use PVDF (polyvinylidene fluoride) material with superior anti-fouling properties, combined with our independently developed membrane fiber weaving process, significantly improving the pressure resistance and cleaning resistance of the membrane modules. Furthermore, the system architecture design incorporates an intelligent monitoring unit that tracks key indicators such as membrane flux and transmembrane pressure difference in real time. Once the system detects a trend of membrane fouling, it automatically initiates an online cleaning process to ensure stable operation.

These technological improvements have earned our ultrafiltration equipment market recognition. After adopting our equipment, a large electronics company in East China saw its production water resistivity consistently maintained above 15 MΩ·cm. Its product qualification rate increase by 3 percentage points, and its production line downtime rate decrease by nearly 20%.

Currently, ultrafiltration water treatment technology is rapidly evolving towards integration, intelligence, and low energy consumption. Our team is focusing on developing integrated treatment units. We combine ultrafiltration with reverse osmosis and nanofiltration technologies to achieve a one-stop service from raw water purification to pure water production. Simultaneously, we are leveraging IoT technology to build an intelligent remote operation and maintenance cloud platform, enabling real-time transmission of equipment operation data, anomaly warnings, and remote diagnostics, providing customers with more efficient after-sales support.

Summarize

In the future, breakthroughs in membrane material technology will further improve the filtration accuracy and service life of ultrafiltration membranes. And the initial investment cost of equipment will gradually decrease. These measures will allow more small and medium-sized enterprises to enjoy the development dividends brought by efficient water treatment technology.