Freshwater resources account for only 2.5% of the Earth’s surface, and water scarcity has become a major global problem. Desalination water treatment equipment has become a core tool for solving this dilemma, resulting in numerous technological benchmarks and classic application cases.

What are the main technologies for desalination equipment?

Reverse osmosis technology is currently the mainstream technology in the field of desalination. Saudi Arabia, as the country with the highest seawater desalination output in the world, has fully demonstrated the mature application level of this technology in its related projects.

Shuaiba 3 Independent Water Project

The Al-Shuaiba 3 Independent Water Project in Saudi Arabia features a reverse osmosis desalination system with a daily processing capacity of 600,000 cubic meters, meeting the daily drinking water needs of 2 million people. The project utilizes high-efficiency reverse osmosis membrane modules paired with a 6.6 MW medium-pressure integrated inverter system, successfully controlling water consumption to 2.773 kWh per ton. Through an innovative membrane housing layout design, plugs are installed at the product water pipelines of the third and fourth membranes, achieving effective separation of high and low salinity product water. This reduces energy consumption in the pressurization process and further improves the quality of the effluent, perfectly adapting to the extreme natural conditions of the Middle East, characterized by high temperature and high salinity.

If Saudi Arabia’s project represents the highest level of large-scale land-based seawater desalination equipment, then Norway’s seabed desalination project has opened up entirely new application scenarios.

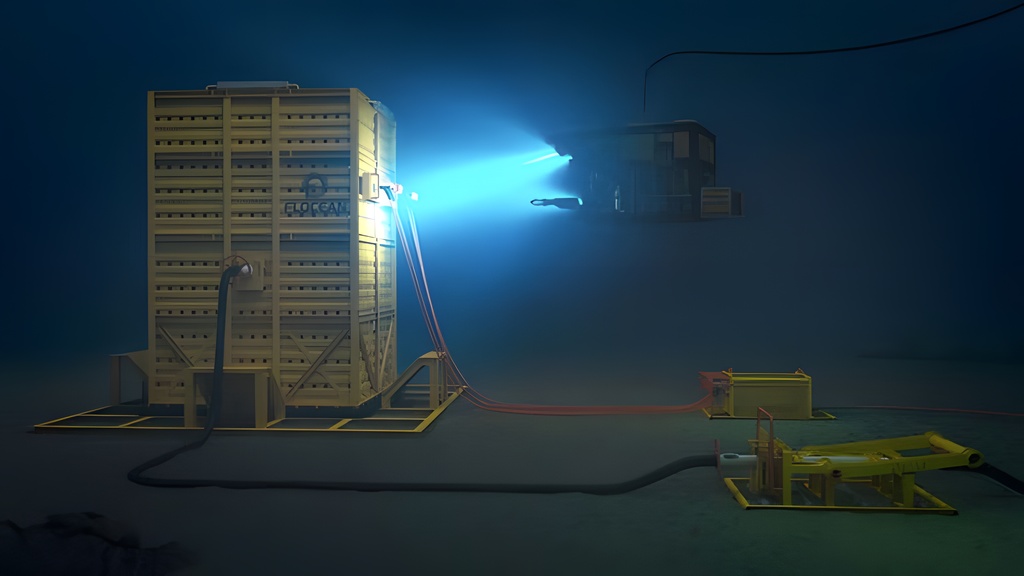

Flocean One Subsea Desalination Plant

A Norwegian startup has developed “Flocean One,” a subsea desalination plant scheduled to begin operation in the first half of 2026. This will be the world’s first commercially operational subsea desalination facility. The equipment abandons the traditional land-based plant design, instead utilizing the natural hydrostatic pressure of the 300-600 meter deep ocean to drive seawater infiltration. Compared to traditional land-based equipment, energy consumption can be reduced by 30% to 50%. Simultaneously, the extremely low levels of bacteria and organic pollutants in the deep-sea environment simplify the pretreatment process. Furthermore, its modular design allows a single module to meet the daily water needs of 37,500 people, with capital investment per unit of capacity reduced by 7 to 8 times compared to traditional solutions.

Desalination water treatment equipment is becoming environmentally friendly

The technological evolution of seawater desalination equipment has consistently focused on two core directions, energy efficiency optimization and ecological compatibility.

The Saudi Shuaiba 3 project includes a 65 MW photovoltaic power station, which can provide 150 million kWh of green electricity annually, replacing traditional oil-fired power generation. This not only reduces the unit water price by $0.013 to $0.022 per cubic meter but also reduces the consumption of 150,000 tons of standard coal.

Norway’s seabed desalination facilities minimize their impact on the marine ecosystem through designs that harmlessly treat chemical agents and avoid discharging concentrated brine into ecologically sensitive areas.

From continuous iteration of desalination technology to innovative breakthroughs in application models, we have promoted the coordinated development of the energy and environmental protection sectors. With the deep integration of photovoltaic, energy storage technologies and desalination equipment, and the widespread adoption of innovative forms such as subsea and modular systems, we will deploy these devices in more water-scarce regions around the world, injecting continuous momentum into building a sustainable global water security system.