In the field of water treatment, ultrafiltration vs reverse osmosis are two key membrane separation processes, widely used in pure water preparation, wastewater recycling, and material concentration and purification. Although both use pressure as the driving force to separate substances, their application range and treatment effectiveness differ significantly due to fundamental differences in membrane structure and separation precision.

This article will analyze the differences and adaptation logic between the two from three dimensions: technical principles, core characteristics, and applications, providing a practical reference for process selection.

Ultrafiltration vs reverse osmosis : different technical principles

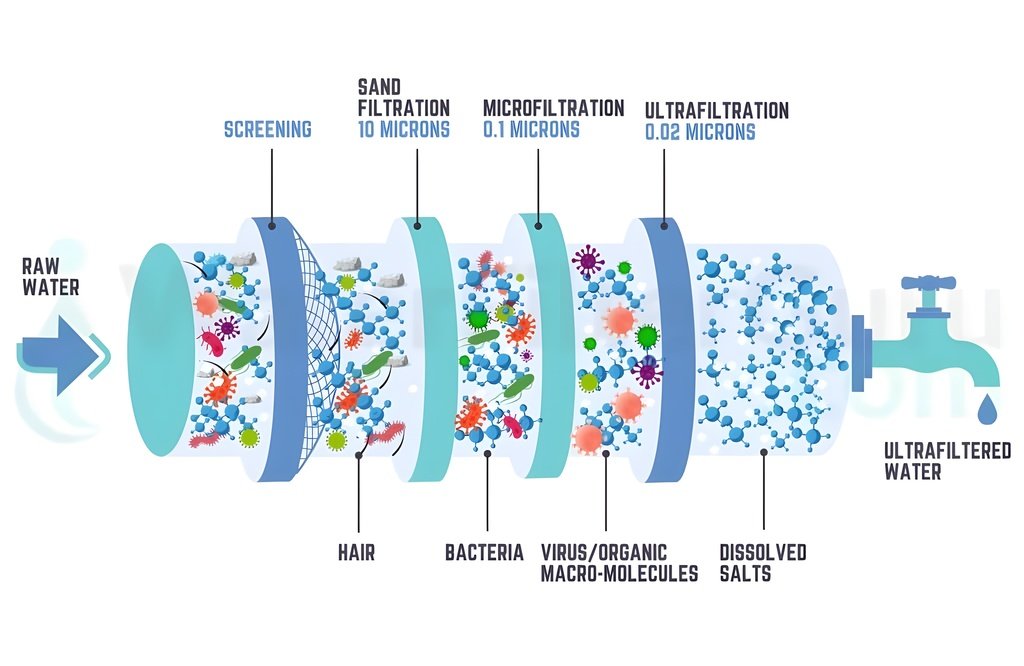

Ultrafiltration technology uses porous membrane elements as its core, with pore sizes typically controlled between 0.01 and 0.1 micrometers, and operating pressures maintained at a low level (0.1-0.5 MPa). Its separation mechanism relies on physical sieving, retaining only suspended solids, colloidal particles, bacteria, and large organic molecules in the water, while water molecules, small salt molecules, and dissolved organic matter can easily permeate the membrane. In practical applications, ultrafiltration membranes often employ hollow fiber or tubular structures, offering advantages such as high flux and strong antifouling performance, enabling deep purification and pretreatment of raw water.

Reverse osmosis technology uses dense semi-permeable membrane materials with a pore size of only 0.0001 micrometers, requiring higher operating pressures (1-10 MPa). Its separation principle is based on the reverse process of osmosis. Engineers apply external pressure that exceeds the solution’s osmotic pressure to force water molecules to permeate through the membrane layer individually, and effectively retain nearly all salts, organic matter, microorganisms, and other impurities in the water. The desalination rate can reach over 99%, making it a core technology for the production of high-purity water.

Ultrafiltration vs reverse osmosis : different core features

Energy efficiency

Ultrafiltration technology can efficiently remove colloids and microorganisms, control the turbidity of treated water to below 0.1 NTU, and achieve a 99.9% bacterial removal rate. However, it has no effect on removing dissolved salts, and the resistivity of the treated water is usually only tens to hundreds of kilohm-cm, which cannot meet the requirements of high-purity water production. In contrast, reverse osmosis technology can achieve deep desalination and comprehensive impurity removal, with an effluent resistivity of 1-18 megohm-cm, and can directly produce pure water or ultrapure water that meets production standards.

Operation and maintenance

Because ultrafiltration operates at low pressure and has a slow membrane fouling rate, its energy consumption is only 1/3 to 1/5 of that of reverse osmosis systems, and its cleaning cycle is longer (usually once every 1-3 months), resulting in relatively lower maintenance costs. Reverse osmosis systems, on the other hand, require high-pressure operation, leading to significantly higher energy consumption. Furthermore, their membrane elements have stringent requirements for feed water quality (turbidity must be controlled at <0.1 NTU, SDI <5), making them susceptible to fouling and increasing the frequency of cleaning, resulting in relatively higher subsequent maintenance costs. In addition, the lifespan of ultrafiltration membranes is generally 3-5 years, while that of reverse osmosis membranes is 2-3 years, leading to a significant difference in membrane element replacement costs.

Different application levels

Ultrafiltration technology is often used as a pretreatment process to ensure the stable operation of subsequent reverse osmosis systems. In pure water preparation processes in industries such as electronics, chemicals, and pharmaceuticals, ultrafiltration can efficiently remove colloids, suspended solids, and microorganisms from raw water, preventing fouling and clogging of the reverse osmosis membrane, extending the lifespan of membrane elements, and improving the overall system’s operational stability.

Simultaneously, engineers can also apply ultrafiltration directly to the pretreatment stage of wastewater reuse—for example, clarifying dyeing and printing wastewater and papermaking wastewater, and conducting side-stream filtration purification for circulating cooling water.

Reverse osmosis technology focuses on advanced water treatment and high-purity water production. In applications with extremely high water quality requirements, such as boiler feedwater in the power industry, chip manufacturing water in the electronics industry, and injection water in the pharmaceutical industry, reverse osmosis can effectively remove salts and organic matter from water, meeting stringent standards for water quality in production processes.

Furthermore, engineers widely apply reverse osmosis technology to seawater desalination, brackish water desalination, and industrial wastewater recycling projects—for instance, to recover and reuse heavy metals and salts from electroplating wastewater.

In practical water treatment projects, engineers often combine ultrafiltration and reverse osmosis to form an integrated “UF+RO” process. Ultrafiltration is responsible for pretreatment, while reverse osmosis is responsible for deep desalination and purification. The two work together to effectively reduce the operation and maintenance costs of the reverse osmosis system and ensure the stability of the effluent quality. This is currently the mainstream technical solution for high-purity water preparation and wastewater resource utilization.

Selection Recommendations

When selecting a treatment process, we need to comprehensively consider factors such as effluent quality standards, treatment scale, and operating cost budget.

If the only requirement is to remove colloids and microorganisms from the water to achieve wastewater clarification or pretreatment, ultrafiltration technology is the preferred choice.

If a project requires deep desalination, high-purity water production, or salt resource recovery, engineers should use reverse osmosis technology.

For scenarios with stringent water quality requirements, a combined UF+RO process is recommended, ensuring both treatment effectiveness and system economy.