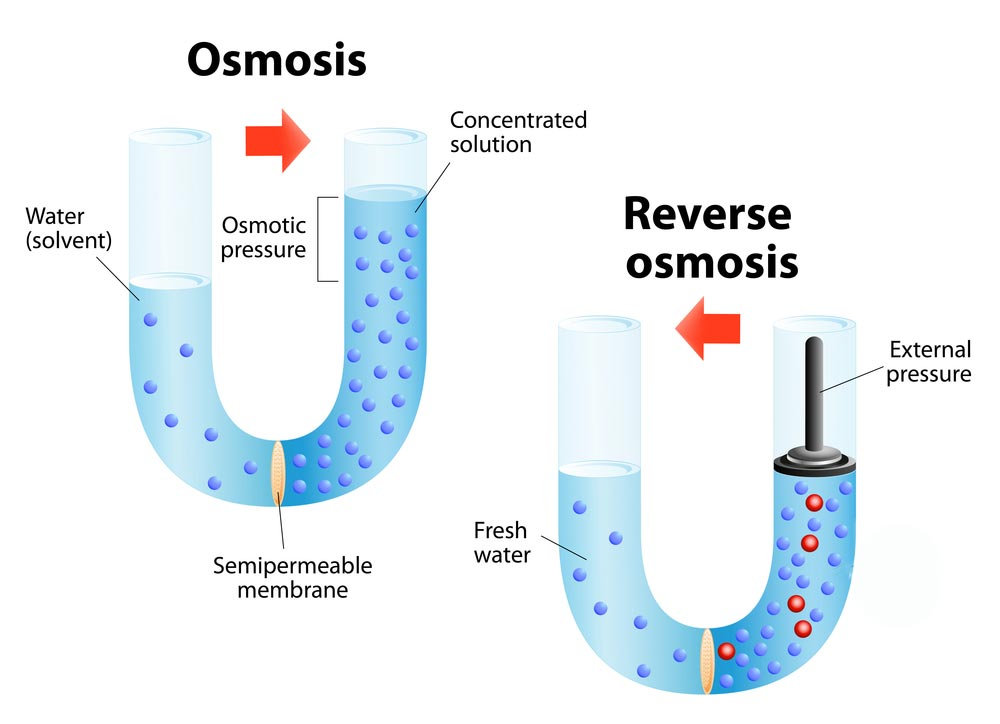

How does reverse osmosis desalination machine work? To understand the working principle of this equipment, we must first clarify the meanings of osmosis and reverse osmosis.

What is penetration?

When a semipermeable membrane separates fresh water and salt water, the fresh water (lower concentration) will naturally flow to the salt water (higher concentration) side until the osmotic pressure on both sides is balanced. In short, the lower concentration flows to the higher concentration.

What is reverse osmosis?

Applying external pressure exceeding the natural osmotic pressure to the brine side forces water molecules in the brine to flow backward through the semi-permeable membrane towards the freshwater side, while salt ions and impurities are retained by the membrane.

The natural osmotic pressure of seawater is approximately 2.4-3.0 MPa. To treat concentrated wastewater, reverse osmosis technology is required. Therefore, the equipment needs to provide significantly higher pressure to force water molecules to flow backward through the reverse osmosis membrane.

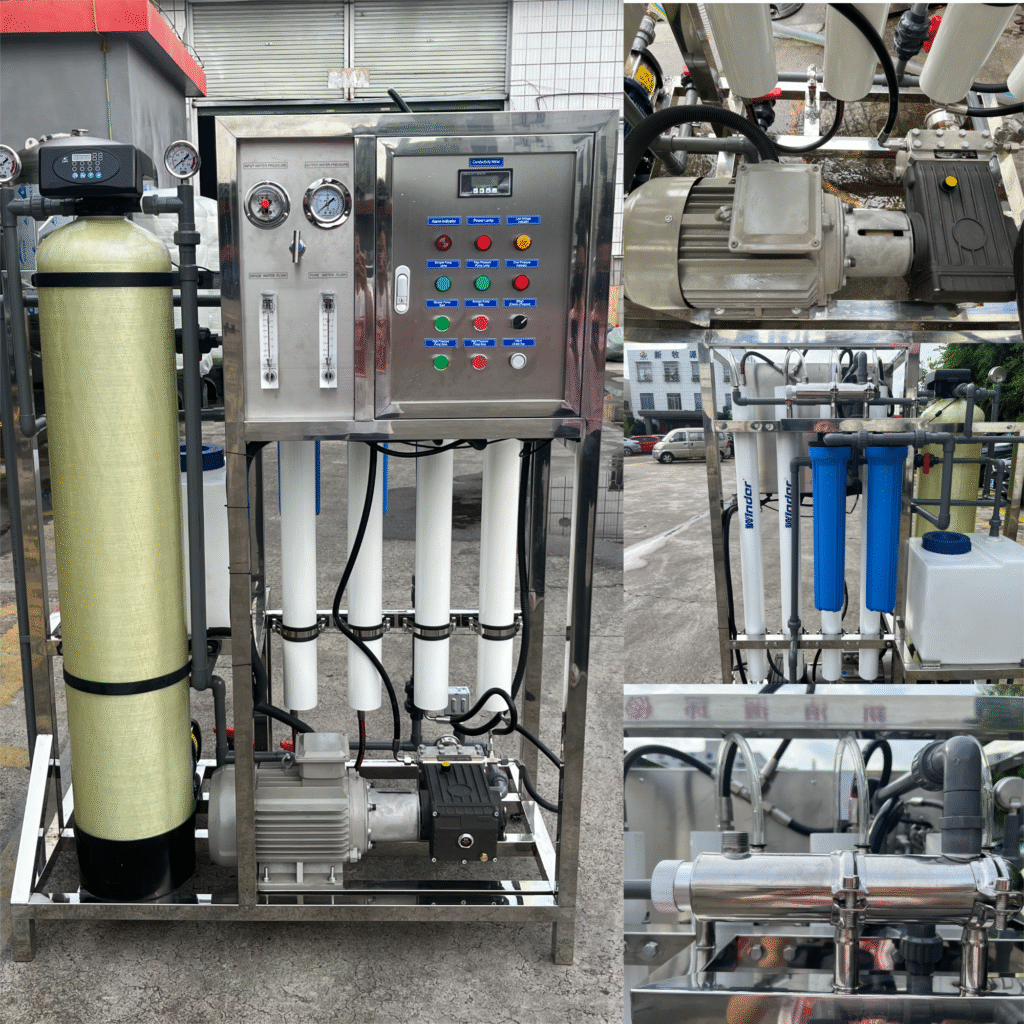

What are the components of a reverse osmosis desalination machine?

Currently, most reverse osmosis desalination machine on the market is a modular system, mainly composed of a pretreatment system, a pump body, membrane modules, and a posttreatment system.

① Preprocessing system:

- Function: Removes suspended solids, colloids, microorganisms, organic matter, and other impurities from seawater, preventing subsequent RO membrane contamination, clogging, or damage.

- Core components: quartz sand filter (filters large particles of impurities), activated carbon filter (adsorbs organic matter and odors), security filter (precision filtration, pore size usually 5μm, intercepts fine impurities), bactericide (such as sodium hypochlorite), and scale inhibitor addition device (prevents calcium and magnesium ions from forming scale).

② High-pressure pump:

- Function: To pressurize the pretreated water so that reverse osmosis technology can be performed.

- Equipment Requirements: The pump must be resistant to high temperatures and corrosion, and possess high pressure stability. We need construct it from stainless steel, and we recommend pump bodies from reputable brands such as CNP (China), Grundfos (Denmark), and KNKE (USA) to guarantee quality.

③RO membrane module:

- Function: The RO membrane retains impurities, salt ions, and other substances, allowing it to desalinate seawater into fresh water. The membrane structure adopts a spiral wound membrane element, which consists of multiple layers of semi-permeable membranes, a flow guide mesh, and a spacer mesh. This membrane structure increases the surface area for separating substances.

- Membrane characteristics: The pore size is only 0.1-1 nanometers, allowing only water molecules to pass through. It has a sodium chloride rejection rate of over 97% and can also intercept heavy metals, bacteria, viruses, etc.

④ Post-processing system:

- Optimize water quality: Although reverse osmosis water is pure, it lacks minerals and may have a low pH value, requiring the addition of a mineralization device and an ultraviolet/ozone sterilizer. This improves taste and kills residual microorganisms, ensuring water quality meets standards.

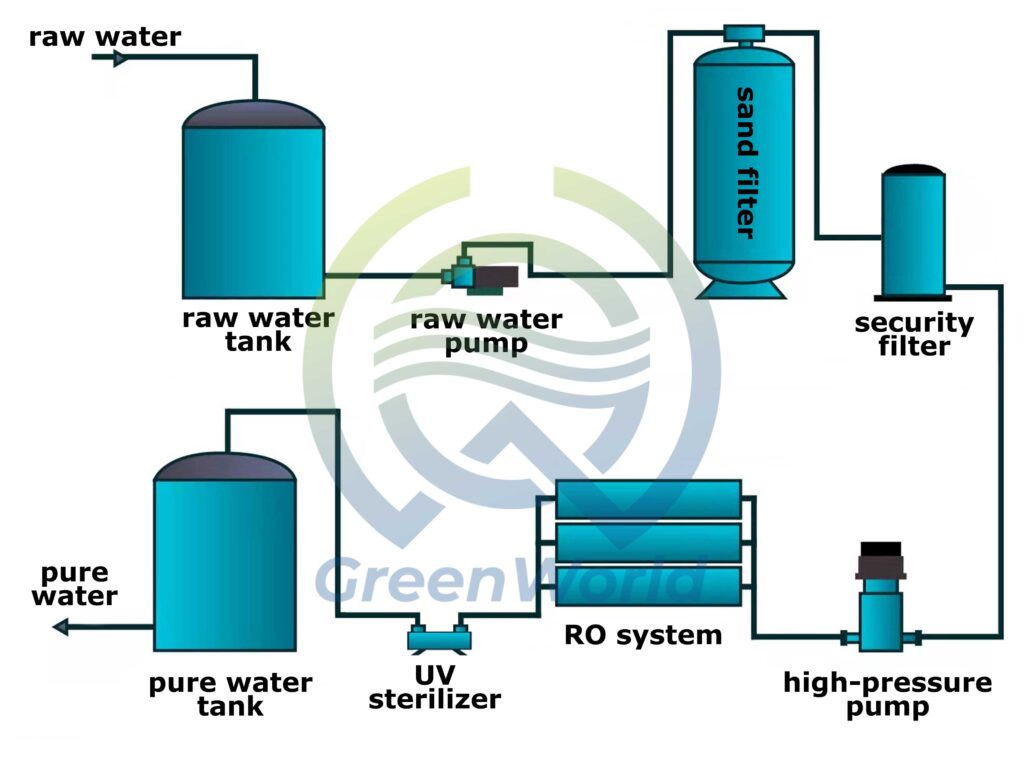

How does a reverse osmosis desalination machine work?

The entire RO desalination system can be divided into four key steps to treat raw water, ultimately turning seawater into freshwater.

Pretreatment Stage:

Seawater first enters the pretreatment system to remove large particles and organic matter. Then, the system adds bactericides and scale inhibitors, and finally, the security filter performs precision filtration on it to obtain the first batch of purified water.

High-Pressure Pressurization:

A high-pressure pump draws in the purified water from the first batch and pressurizes it to 10-80 MPa before sending it into the RO membrane module.

Reverse Osmosis Separation:

As the high-pressure seawater flows through the RO membrane module, water molecules pass through the reverse osmosis membrane under pressure, becoming “freshwater.” It will retains salt ions (sodium, chloride), heavy metals, microorganisms, etc., forming “concentrated brine.”

Post-Treatment System:

At this stage, we need to adjust the pH value, add minerals, and disinfect. Finally, the purified water becomes freshwater that meets drinking or industrial standards.

Why has reverse osmosis desalination become the mainstream?

Compared to traditional seawater desalination technologies such as distillation, reverse osmosis desalination has more potential and advantages.

- Low energy consumption: With the help of energy recovery technology, the energy consumption per unit of water produced by the RO system is currently only 1/3 to 1/2 of that of the distillation method. We can also choose solar desalination technology, which converts light energy into electrical energy through solar photovoltaic panels, directly driving high-pressure pumps, water pumps in the pretreatment system, and post-treatment disinfection equipment, forming an integrated “photovoltaic-reverse osmosis (PV-RO) system”.

- High water purity: RO technology can reduce the salinity of freshwater to below 500 mg/L, and can even achieve ultrapure water levels.

- Small footprint: The membrane module has a compact structure, and a set of RO desalination equipment with a daily output of 10,000 tons occupies only about 1/10 of the area of the distillation method.

- Easy to operate: High degree of automation, requiring only a small number of personnel for maintenance, and strong operational stability.

Summarize

In other words, this type of equipment uses reverse osmosis technology to force water molecules in the seawater to pass through the reverse osmosis membrane in the opposite direction to enter the freshwater side. The membrane retains impurities such as salt ions, heavy metals, and microorganisms, ultimately producing freshwater that meets standards.

If you need a quote for this type of equipment, please feel free to contact us.