EDI-system Elektrodeionisering

Including water treatment equipment and engineering projects,adhere to the business philosophy of high quality and good service,fully meet customer needs,provide customers with advanced equipment,fundamentally solve customer problems,and create the greatest value for customer.

EDI-system Elektrodeionisering

EDI equipment, as a green and innovative device that integrates electrodeionization and ion exchange technologies, can continuously produce high-purity ultrapure water without the need for acid-base chemical regeneration. It completely solves the pain points of traditional water treatment processes, such as water production interruption, pollution discharge, and high costs, and has become the core preferred choice for modern industrial ultrapure water systems.

| Desalting Rate | More than 97% |

| Water Recovery | About 50-65% |

| Voltage | 220v 380V 50HZ 60HZ(Or Customized) |

| RO membrane | DOW Membrane USA Original Vontron |

| High pressure pump | CNP |

| Raw water pump | Lingxiao |

| Filter Media | Sand+Carbon+Softener |

| Certification | CE ISO |

Product Details

EDI system electrodeionization is a continuous electro-deionization equipment. It actually combines the characteristics of ion exchange resin and ion selective permeable membrane. In other word, it can deeply remove ionic impurities in water and produce high-purity water.

Our factory accepts customization of different specifications, from 250 LPH to 100 TLPH. Regarding the power sector, we can also customize solar container equipment if needed.

How do EDI system electrodeionization work?

Below, I will explain the working principle of edi system.

It combines ion exchange with electric drive. Under the traction of electric field force, anions and cations in water migrate to the concentrated water chamber through selective ion exchange membranes respectively, continuously removing almost all ionic impurities in the water. Thereby preparing high-purity ultrapure water efficiently and stably without the need for large amounts of acid and alkali regeneration.

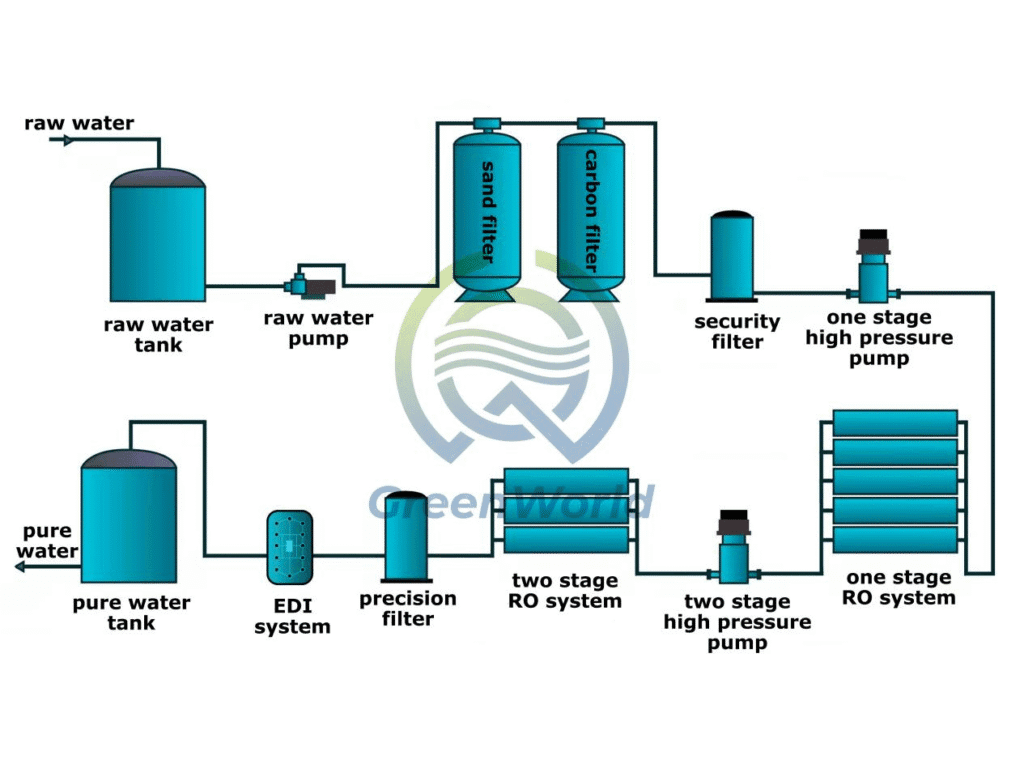

Water purification can be mainly divided into four steps.

1.Pretreatment

Firstly, pretreatment is the first step in the workflow of EDI system. It’s aim is to remove impurities such as suspended solids, dissolved oxygen, organic matter and bacteria in raw water.

2.Reverse Osmosis (RO) System Treatment

Secondly, the reverse osmosis system uses the selective permeability of the semipermeable membrane to remove dissolved solids, inorganic salts and microorganisms in the water to produce high-purity desalted water.

3.EDI System Electrodeionization Treatment

Thirdly, the EDI system electrodeionizationcombines the principles of electrochemical reaction and ion exchange to achieve deep removal of ions.

4.Subsequent treatment and storage

Finally, to prevent secondary contamination of pure water during storage and distribution, UV ultraviolet sterilizers are usually installed. After the above treatment, pure water enters the water storage tank or pure water tank for storage. And We will distribute pure water to various water use points as needed.

Advantages of EDI system electrodeionization

1.Technology integration

EDI system combines electrodialysis and ion exchange technology, drives ion migration through electric fields. It uses ion exchange resins for ion removal and regeneration, achieving an efficient and continuous desalination process.

2.Modular design

EDI system usually adopts a modular structure, which is easy to install, debug and maintain. Because of this design, it allows the equipment to be flexibly configured according to actual needs. Thus, meet different treatment scales and water quality requirements.

3.High effluent quality

EDI electrodeionization systems can produce high-quality ultrapure water with stable water quality and resistivity of more than 15MΩ·CM. So,it can meet the high-purity water needs of electronics, medicine, chemical industry, etc.

4.Energy saving and environmental protection

Compared with traditional ion exchange equipment, EDI system does not need to use acid and alkali for resin regeneration. Therefore, it is able to reduce acid and alkali consumption and wastewater discharge, and reduce environmental pollution.

5.Stable operation

Because EDI system is not affected by external conditions such as time, pressure and temperature during operation, and the effluent quality is stable and reliable. There will be no fluctuation or decline in water quality.

VORES FABRIK

WORKSHOPS

Guangdong Xinyuanyuan Environmental Protection Technology Co, Ltd. blev grundlagt i 2018 og er en integreret miljøvirksomhed med speciale i videnskabelig forskning, produktion og salg, der har et professionelt team på 20 til 99 medlemmer og et veludstyret anlæg på ca. 1.800 kvadratmeter i Panyu District, Guangzhou, Kina. Virksomheden er strategisk placeret i kernen af Perleflodsdeltaet og udnytter sin førsteklasses beliggenhed til at understøtte effektiv drift, udvide forretningen på tværs af landbrug, kemiteknik, medicinsk behandling og fødevareforarbejdningsindustrier (der dækker forskning og udvikling af miljøudstyr, vand-/slambehandling og økologisk restaurering) og lette problemfri import-eksportoperationer for globale kunder.

OFTE STILLEDE SPØRGSMÅL

Vi tilpasser udstyrsparametre og behandlingsløsninger baseret på dit vandbehov (f.eks. vandkvalitet, spænding, proces osv.), og alle produkter overholder internationale universelle standarder (herunder ISO, CE osv.) med komplette certificeringsdokumenter. Fra valg af udstyr og installationsvejledning til vedligeholdelse efter salg tilbyder vores professionelle tekniske team support i hele cyklussen. Ved at udnytte vores globale samarbejdslogistiknetværk sikrer vi hurtig levering med en svartid efter salg på højst 24 timer, hvilket fuldt ud løser eventuelle problemer, du måtte have under indkøb og brug i udlandet.