Electrodeionization system is the core of high-purity water production. High-purity water is an essential resource for industries like industry, medicine, and electronics. As the quality of water required in these fields directly impacts product performance and production safety.

Definition of Electrodeionization System (EDI)

Electrodeionization (EDI) is an advanced water purification technology. It integrates the functions of ion exchange resin (IER) and electrodialysis (ED) under the action of an electric field. Through the synergistic effects of ion migration, ion exchange, and in-situ resin regeneration. It achieves deep removal of ionic impurities (such as sodium, chloride, calcium, and magnesium ions) from water. Unlike traditional ion exchange systems that require chemical regeneration with acids and alkalis, EDI utilizes hydrogen ions (H⁺) and hydroxide ions (OH⁻) generated by water electrolysis to continuously regenerate the ion exchange resin. Thereby, achieve the consistent and stable production of high-purity water.

EDI is a “green purification technology” that eliminates chemical regeneration agents. Its goal is to produce water with a resistivity as high as 18.2 MΩ·cm (close to theoretically pure water) while minimizing environmental pollution and operating costs.

How does an electrodeionization system work?

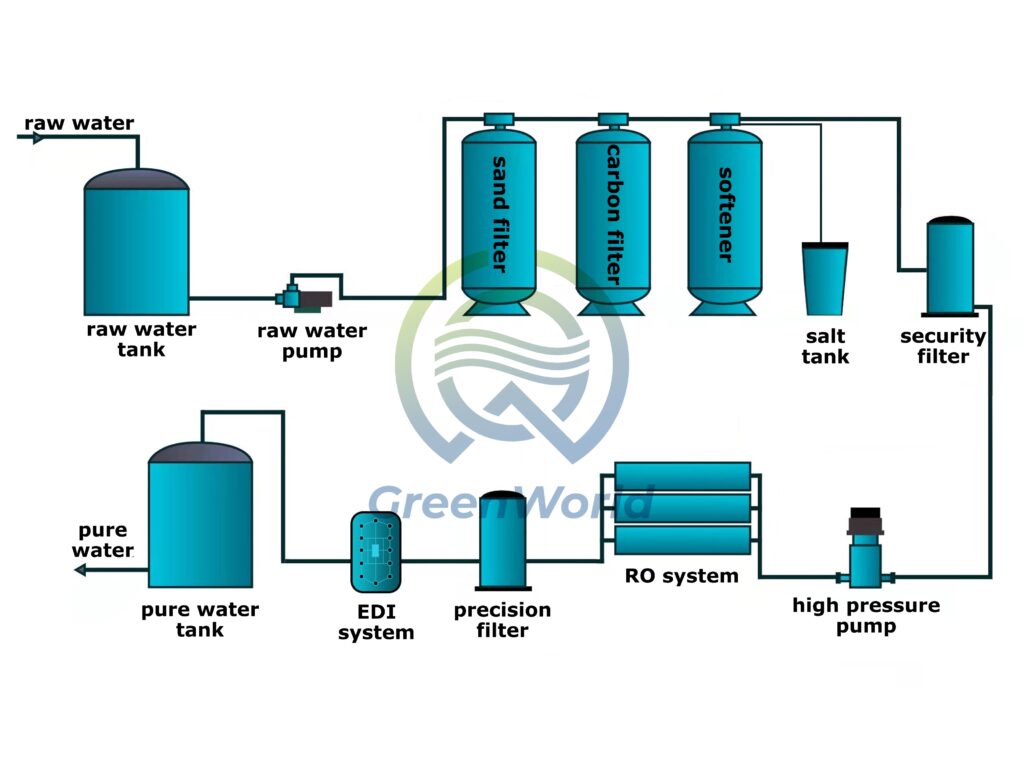

The electrodeionization system can be simplified into the following four key steps. According to the process of “pretreatment – rough purification – deep purification – water production guarantee”.

Firstly, raw water pretreatment

First, filter the raw water (such as quartz sand filtration and activated carbon adsorption) to remove impurities such as suspended matter, colloids, and residual chlorine to avoid subsequent RO membrane blockage or oxidation damage, and provide qualified feed water for the RO system.

Secondly, ro system rough purification

After pre-treatment, pressurized water enters the RO membrane module. The membrane allows only water molecules to pass through, while retaining over 90% of ions (such as sodium and calcium), organic matter, and microorganisms. This produces “primary pure water” (typically with a resistivity of 1-10 MΩ·cm), while simultaneously discharging concentrated water containing high levels of impurities.

Thirdly, Deep Cleansing of the EDI System

RO produced water enters the EDI module and under the action of the electric field:

①The residual trace ions in the water migrate in a directional manner, and the ion exchange membrane separates them.

②Ion exchange resin adsorbs the remaining ions.

③ H⁺ and OH⁻ produced by water electrolysis can be used to regenerate resin in situ without the need for chemical agents.

The final output is high-purity water with a resistivity of 15-18.2 MΩ・cm.

Finally, produced water storage

The high-purity water produced by EDI is stored in a dedicated water tank. The system monitors RO/EDI operating parameters (such as pressure and water quality) in real time and adjusts the water flow through automatic valves to ensure stable water production throughout the process.

Why use an EDI system to prepare pure water?

Environmentally friendly and pollution-free: No acid or alkali regeneration is required, and no waste liquid is discharged.

Low operating costs: Reduce chemical procurement, storage, and handling costs.

Stable water quality: The resistivity can be maintained at 15-18.2 MΩ・cm over a long period of time, with minimal fluctuation in water quality, meeting the needs of high-end industries.

Easy maintenance: Users do not need to replace the resin frequently. We only need to clean the membrane and electrodes regularly, minimizing the maintenance workload.

Summarize

In the future, EDI system will undergo multi-dimensional innovation and development. Both large-scale and small-scale development (developing equipment tailored to specific scenarios) and synergy (integrating with technologies like RO and UF builds multi-stage water treatment systems to expand application scenarios).

If you require this type of equipment, please feel free to contact us.