Beer is a fermented beverage, and water quality plays a decisive role in its taste, flavor purity, and quality stability. There is a long-standing consensus in the industry that “water is the foundation of beer.”

With the rapid scaling up of beer production, traditional water treatment processes are becoming increasingly inadequate for the demands of large-scale, high-standard production. Therefore, large ro system has become a core component of modern brewery water treatment due to their superior impurity removal capabilities, stable operation, and energy efficiency.

What are the water quality requirements for breweries?

Beer brewing demands extremely high water quality standards. System must not only thoroughly remove visible impurities such as suspended solids, colloids, and microorganisms, but also precisely control key indicators like heavy metal ions, organic pollutants, and water hardness.

For example, excessive calcium and magnesium ion content in the water can cause sedimentation in the beer, damaging its appearance. Excessive organic matter, on the other hand, can interfere with the yeast fermentation process, ruining the beer’s pure flavor.

Why use a large RO system?

In large-scale production scenarios, the efficiency and cost control of water treatment in breweries directly impact a company’s market competitiveness.

Large RO system possesses continuous and stable water production capabilities, with a single unit capable of producing hundreds or even thousands of tons of water per day. This allows for precise matching of the batch production rhythm of large breweries, effectively preventing production stoppages caused by water supply shortages.

Simultaneously, the system can flexibly adjust operating parameters according to production load, reducing energy consumption during off-seasons and achieving efficient energy allocation.

In addition, the wastewater discharge volume of the RO system is much lower than that of traditional processes. And the treated concentrate can be recycled for purposes such as irrigation of green areas in the factory and washing of production equipment, which significantly improves the utilization rate of water resources.

How does large RO system improve water quality?

Large RO system utilizes selective sieving and permeation technology with semi-permeable membranes to efficiently remove over 97% of impurities from water under high pressure, producing pure water that fully meets the Class I water quality standards for beer brewing. Therefore, we avoid the negative impact of poor water quality on beer quality from the source.

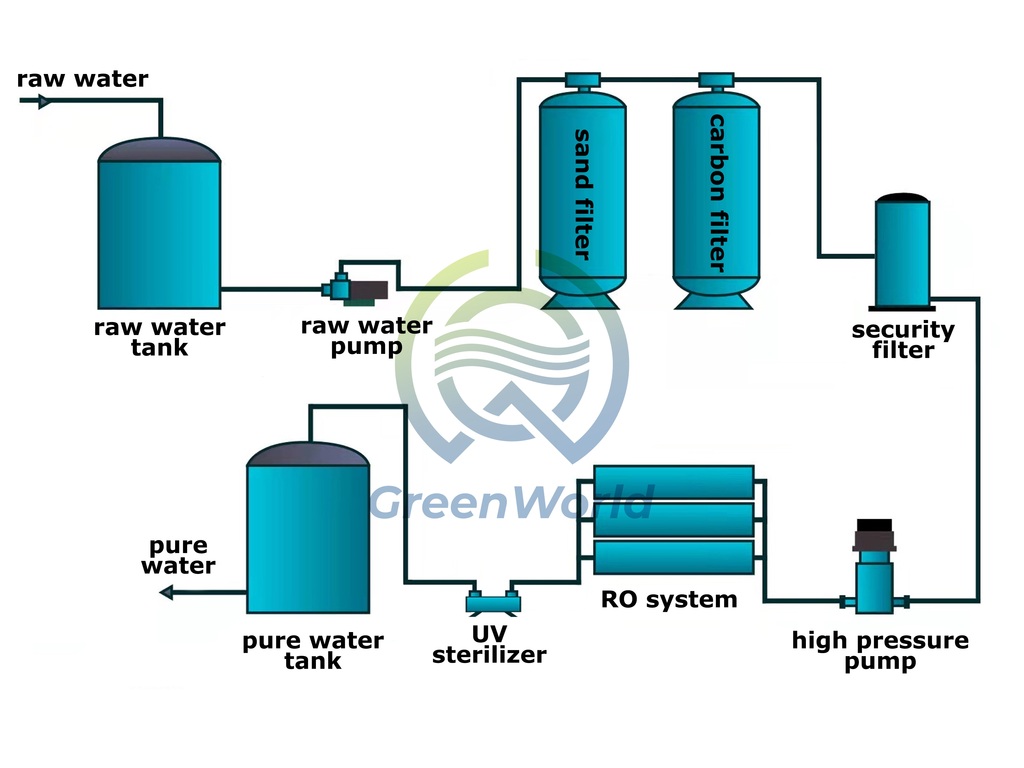

In actual production, breweries typically incorporate pretreatment processes such as quartz sand filtration, activated carbon adsorption filtration, and security filtration upstream of the RO system. The purpose is to remove large suspended solids, colloidal impurities, and residual chlorine from the raw water, preventing irreversible fouling of the RO membrane elements and extending their lifespan. Furthermore, industrial-grade RO systems are equipped with an online monitoring and chemical cleaning (CIP) automatic control module. It can monitor key process parameters such as permeate conductivity, pH value, and membrane pressure differential in real time. When parameters exceed set thresholds, the cleaning program is automatically initiated, significantly reducing manual maintenance workload and ensuring long-term stable system operation.

Carlsberg, a renowned Danish brewery, has implemented a comprehensive water management demonstration project at its Frederica plant. They introduced a closed-loop reverse osmosis (CCRO) system as the core purification unit. After process integration, we not only brought the key indicators of brewing water up to brewing-grade standards, but also achieved a 90% water reuse rate. Since the project’s implementation, the plant’s water consumption per liter of beer produced has significantly decreased, saving over €1.2 million annually in energy and water-related costs.

Compared to traditional processes such as ion exchange and activated carbon adsorption, large RO system offers superior purification precision and eliminate the need for frequent filter media replacements, effectively simplifying the process and reducing operational complexity.

Zusammenfassend

As consumers continue to demand higher quality beer, breweries will inevitably raise their water treatment standards. Large RO system will achieve further breakthroughs in areas such as intelligent control and energy optimization, providing breweries with better and more suitable water treatment solutions.