Containerisierte Wasseraufbereitungsanlage

Including water treatment equipment and engineering projects,adhere to the business philosophy of high quality and good service,fully meet customer needs,provide customers with advanced equipment,fundamentally solve customer problems,and create the greatest value for customer.

Containerisierte Wasseraufbereitungsanlage

Containerized water treatment plant is a highly efficient and environmentally friendly equipment that integrates advanced water purification technology with standardized container integrated design. It highly integrates the pretreatment system, main unit, intelligent control, cleaning and maintenance and water storage unit in a 20-foot or 40-foot standard container, realizing a closed-loop process from raw water purification to standard produced water.

| Desalting Rate | More than 97% |

| Water Recovery | About 50-65% |

| Voltage | 220v 380V 50HZ 60HZ(Or Customized) |

| RO membrane | DOW Membrane USA Original Vontron |

| High pressure pump | CNP |

| Raw water pump | Lingxiao |

| Filter Media | Sand+Carbon+Softener |

| Certification | CE ISO |

Product Details

The containerized water treatment plant shown in the picture has a production capacity of 30 tons of water per hour. Its core technology is the Umkehrosmose membrane separation technology. Under the pressure higher than the osmotic pressure of the solution, the impurities in the water are separated. Because the reverse osmosis membrane only allows water molecules to pass through. Thereby achieving the purpose of purifying the water quality. Our factory accepts customization of different specifications, from 250 LPH to 100 TLPH.

In addition, the technologies used in container water treatment equipment can include ultrafiltration, seawater desalination, etc. The specific water purification process depends on the water source.

Regarding the power sector, our company can also customize solar container equipment if needed.

How do containerized water treatment plant work?

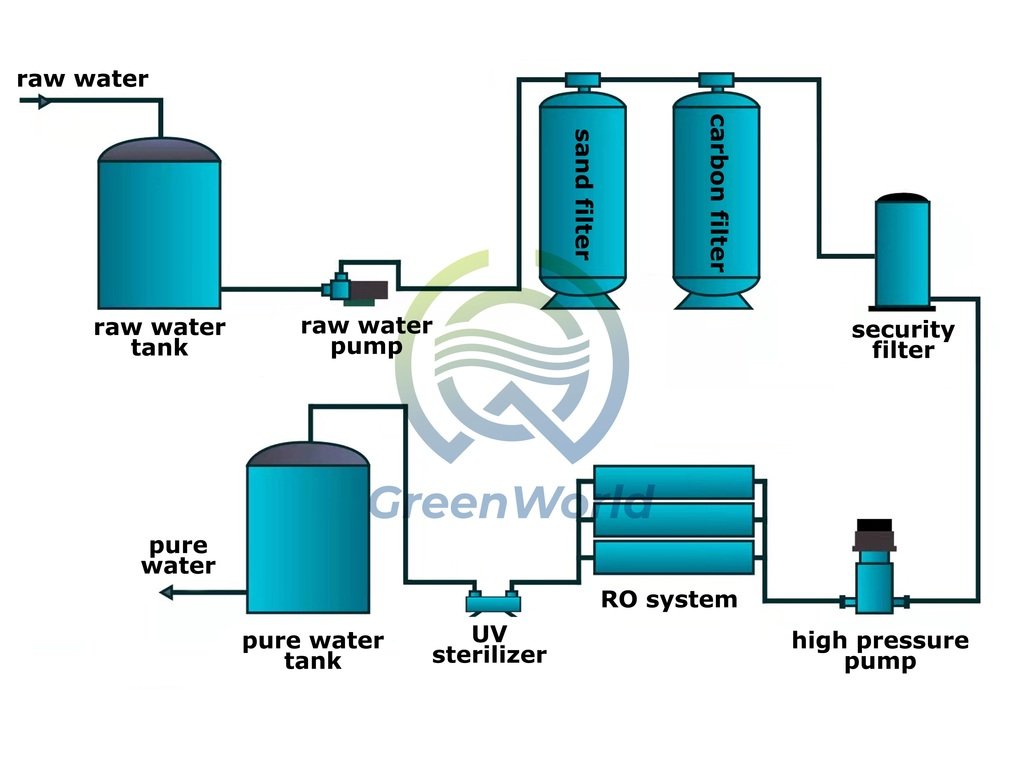

Below, I will explain the working principle of containerized reverse osmosis equipment.

Because of the semi-permeable membrane characteristics of the RO membrane, we can drive high-efficiency purification under pressure. It can significantly reduce the salt content and the purification rate can reach 95% – 99% or more. We use the RO membrane to intercept bacteria, viruses and other large scale RO microorganisms to prevent water quality deterioration. According to the principle of like dissolves like, we remove most organic matter to improve water quality. Water quality is adjusted with the help of regulating devices in the pre-treatment or post-treatment links to meet different needs.

Water purification can be mainly divided into three steps.

1.Pretreatment

Firstly, raw water passes through the raw water tank, raw water pump. And then passes through the multi-media filter (removing suspended matter, etc.), activated carbon filter (removing organic matter, etc. and limiting residual chlorine). If raw water with high hardness, we also needs to pass through the softener (adsorbing calcium and magnesium ions).

2.Reverse osmosis treatment

Secondly, the security filter finely filters the pre-treated water to remove impurities with different precisions to ensure water quality. The high-pressure pump is controlled by multiple factors to supply pressure to the reverse osmosis membrane to achieve material separation. The reverse osmosis membrane assembly allows part of the water to be purified and produced under high pressure, intercepting impurities, and the desalination rate exceeds 98%.

3.Post-treatment and storage

Finally, the clean water after reverse osmosis treatment may have residual microorganisms. Then we need to use ultraviolet lamps, ozone sterilizers, etc, to disinfect. The disinfected water is stored in the pure water tank and transported to the water point by the pure water pump to meet the demand.

Advantages of containerized water treatment plant

1.Modular extension

Utilizing a standard container structure, it can be conveniently transported by road, rail, and sea. The equipment undergoes full pre-assembly and commissioning at the factory, requiring only connection of inlet and outlet water pipes and the power system on-site. It can be started up and put into operation in 1-3 days, improving efficiency by more than 90% compared to the construction cycle of traditional water treatment plants, which takes several months.

2.Strong water production capacity

The water production per hour reaches 30 tons, which can meet large-scale and continuous water demand. Whether it is large-scale industrial production or living water supply in densely populated areas, it can stably supply sufficient water sources.

3.Excellent water quality

The containerized water treatment plant has a desalination rate of over 95%, and because the pore size of the reverse osmosis membrane is as small as 0.0001 microns, it can almost intercept all microorganisms to ensure the safety of water quality microbial indicators. It can also greatly reduce the content of organic matter such as humic acid, and reduce COD and BOD.

4.Stable operation

The machine has a high degree of automation, uses PLC to adjust operating parameters, adjusts the state according to the set value, has high and low pressure protection, water shortage protection and other fault alarms, can operate continuously and stably, and produce water continuously and stably

5.Economical and efficient

The equipment has the advantage of low energy consumption. Advanced reverse osmosis technology optimizes operating energy consumption, reduces long-term costs, has a high recovery rate, can improve water resource utilization, and reduce waste and water costs.

6.Widely used

In the industrial field, it is suitable for electronics, pharmaceuticals, chemicals, food and beverage industries, providing high-purity process water to ensure product quality. Another field of life, we can use containerized equipment systems in communities, schools, hospitals, hotels and other places to supply high-quality drinking water.

UNSERE FABRIK

WORKSHOPS

Guangdong Xinyuanyuan Environmental Protection Technology Co., Ltd., founded in 2018, is an integrated environmental enterprise specializing in scientific research, production and sales, boasting a professional team of 20 to 99 members and a well-equipped facility spanning approximately 1,800 square meters at Panyu District, Guangzhou, China. Strategically situated in the core of the Pearl River Delta, the company leverages its prime location to support efficient operations, expand business across agriculture, chemical engineering, medical care and food processing industries (covering environmental equipment R&D, water/sludge treatment and ecological restoration), and facilitate seamless import-export operations for global clients.

FAQ

Wir passen die Geräteparameter und Aufbereitungslösungen an Ihren Wasserbedarf an (z. B. Wasserqualität, Spannung, Verfahren usw.), und alle Produkte entsprechen den internationalen universellen Standards (einschließlich ISO, CE usw.) mit vollständigen Zertifizierungsunterlagen. Von der Auswahl der Geräte über die Installation bis hin zur Wartung nach dem Verkauf bietet unser professionelles technisches Team Unterstützung über den gesamten Lebenszyklus. Durch die Nutzung unseres globalen kooperativen Logistiknetzes gewährleisten wir eine schnelle Lieferung mit einer Reaktionszeit von höchstens 24 Stunden nach dem Verkauf und lösen alle Probleme, die Sie bei der Beschaffung und Nutzung im Ausland haben könnten.