Currently, industrial water treatment equipment worldwide is constantly being upgraded, and environmental regulations are becoming increasingly stringent. For businesses, an efficient and reliable water treatment solution has become crucial for compliant production and cost savings.

Ultrafiltration water treatment machine, as a core component of membrane separation technology in industry, has become widely used in various factories in China and has successfully entered overseas markets, thanks to its precise filtration, environmental friendliness, energy efficiency, and strong adaptability. It has become a valuable tool for water management in industrial production.

Why is ultrafiltration water treatment machine so crucial?

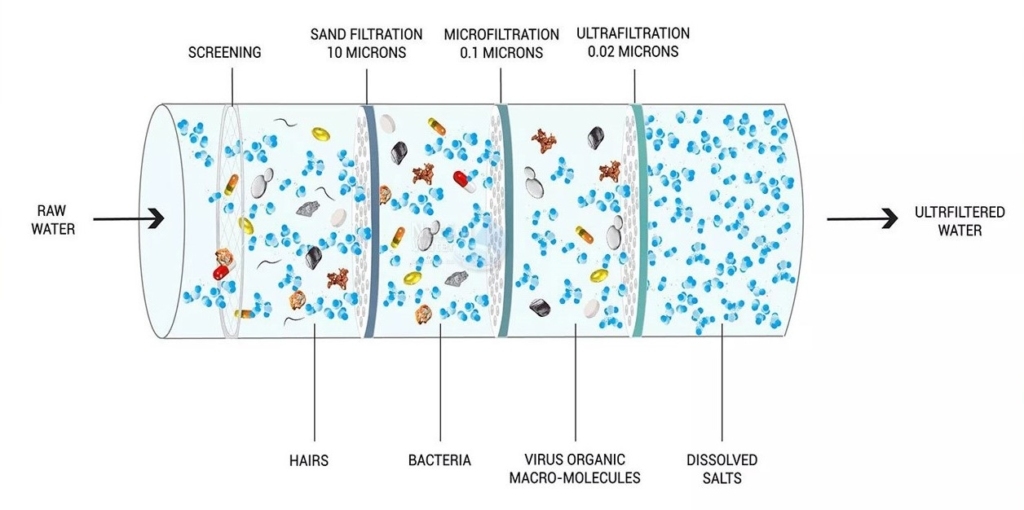

Ultrafiltration membranes have pore sizes ranging from 0.01 to 0.1 micrometers, which are finer than microfiltration membranes but coarser than nanofiltration membranes. They can precisely filter out impurities in industrial wastewater and process water, such as suspended solids, colloids, bacteria, viruses, and large organic molecules. At the same time, water molecules and small mineral molecules useful for production can pass through easily, fully meeting the water quality requirements of industrial production.

Unlike traditional water treatment machines, we don’t require the addition of chemical agents such as flocculants or disinfectants. Instead, we achieve filtration solely through pressure difference. This prevents chemical agents from affecting subsequent production and avoids secondary pollution of wastewater, meeting both domestic and international environmental standards.

What are the advantages?

Designed to meet the needs of industrial production and overseas markets, this ultrafiltration equipment offers three outstanding advantages.

First, it boasts high filtration accuracy and stable operation, adapting to complex industrial water quality conditions. Industrial wastewater contains diverse pollutants with varying concentrations, but this equipment can reliably handle surface water, groundwater, and factory circulating water, ensuring the treated water meets domestic and international industrial water and wastewater discharge standards. In particular, the removal rate of bacteria and viruses exceeds 99.9%, eliminating concerns about substandard water quality affecting production.

Second, it is environmentally friendly and cost-effective. The equipment operates without the need for large quantities of chemical reagents, saving overseas companies on reagent procurement and environmental treatment costs. When the ultrafiltration membrane becomes dirty, we can restore its filtration performance through backwashing and chemical cleaning, extending its lifespan to 3 to 5 years. Furthermore, its modular design makes on-site maintenance very convenient.

Third, it has a wide range of applications and complies with local regulations, meeting the needs of various industries overseas. Whether in the electronics, food, pharmaceutical, or chemical industries, we can customize the equipment according to the factory size.

Where have we deployed our ultrafiltration water treatment machine?

Currently, our company is widely using our ultrafiltration water treatment machine in industrial sectors both domestically and internationally, especially in overseas markets, where we have accumulated a large number of stable customers and application cases.

In the electronics and semiconductor industry, it serves as a pretreatment device for production water, effectively removing trace impurities from the water and ensuring the purity of the water used in the production of chips and components. It has been successfully implemented in electronics industrial parks in Southeast Asia and Europe.

In the food and beverage industry, it efficiently treats production wastewater and process water, allowing for water recycling and meeting the environmental certification requirements of the EU food industry. It has served many well-known overseas food companies.

In the chemical industry, it effectively intercepts pollutants in high-concentration organic wastewater, helping companies reduce water treatment costs. It has already been implemented in chemical parks in the Middle East and Africa.

Furthermore, in the pharmaceutical industry, it can meet the requirements for sterile and high-purity water used in pharmaceutical production, and has passed the certification of the local pharmaceutical industry and gained recognition from local pharmaceutical companies.

Summarize

Taking advantage of the global trend towards industrial environmental protection upgrades, we are accelerating the deployment and technological upgrading of our ultrafiltration water treatment machine. In the future, we will focus on developing industrial-grade ultrafiltration membranes that are more pollution-resistant, have faster filtration speeds, and longer service lives, such as ceramic ultrafiltration membranes and anti-fouling hollow fiber ultrafiltration membranes, to ensure that our equipment can operate efficiently even under complex water quality conditions.