Although water covers 71% of the Earth’s surface, freshwater resources account for less than 2.5% of total water resources. Freshwater directly usable by humans is especially scarce. With continued global population growth and accelerated industrialization, over one-third of the world’s regions are facing a water supply-demand imbalance.

Against this backdrop, many desalination companies are using desalination technology to deliver life-sustaining resources to arid and water-scarce regions, solving the freshwater shortage crisis.

How did the seawater desalination industry develop?

The advancement of the desalination industry has always been driven by enterprise-led innovations in water treatment technology.

Early distillation methods, while capable of desalinating seawater, were hampered by high energy consumption and high costs, hindering their widespread adoption. The advent of reverse osmosis membrane technology in the 1960s revolutionized the seawater desalination industry. Israel’s IDE company pioneered this technology, upgrading membrane filtration precision to the nanometer level, using pressure to force seawater through a semi-permeable membrane to achieve brine separation.

Today, reverse osmosis technology accounts for more than 70% of the global desalination market. And it reduced energy consumption by 60% compared to traditional processes, and lowered the cost of desalinated water to $1 to $3 per ton.

Although China’s desalination companies started late, domestic companies have continuously broken through technological barriers.

Tianjin Membrane Technology’s anti-fouling reverse osmosis membranes can still operate stably in high-turbidity seawater, breaking the foreign technological monopoly. The Liuhang Island desalination project in Zhoushan, Zhejiang, undertaken by China Power Construction Corporation. They uses a combined process of “membrane technology + emergency distillation” to achieve tiered supply of domestic and industrial water.

What problems do seawater desalination companies face?

However, desalination companies still face the dual challenges of ecological protection and cost control.

① Direct discharge of concentrated brine may damage marine ecosystems. ② Water transportation costs to remote areas remain high.

In response, global desalination companies are not merely reacting passively. But they are actively exploring targeted solutions based on their technological advantages and regional characteristics.

For example, Singapore’s Hyper Group has developed a concentrated brine mineral extraction technology, turning waste into treasure. Spain’s Abengol has optimized its energy recovery system in a Saudi project, reducing energy consumption for concentrated brine discharge by 25% and minimizing its impact on the sea. Chinese state-owned enterprises are promoting a “desalination + water storage + intelligent scheduling” system on islands, using energy storage equipment to balance water supply fluctuations.

What projects have the desalination companies implemented?

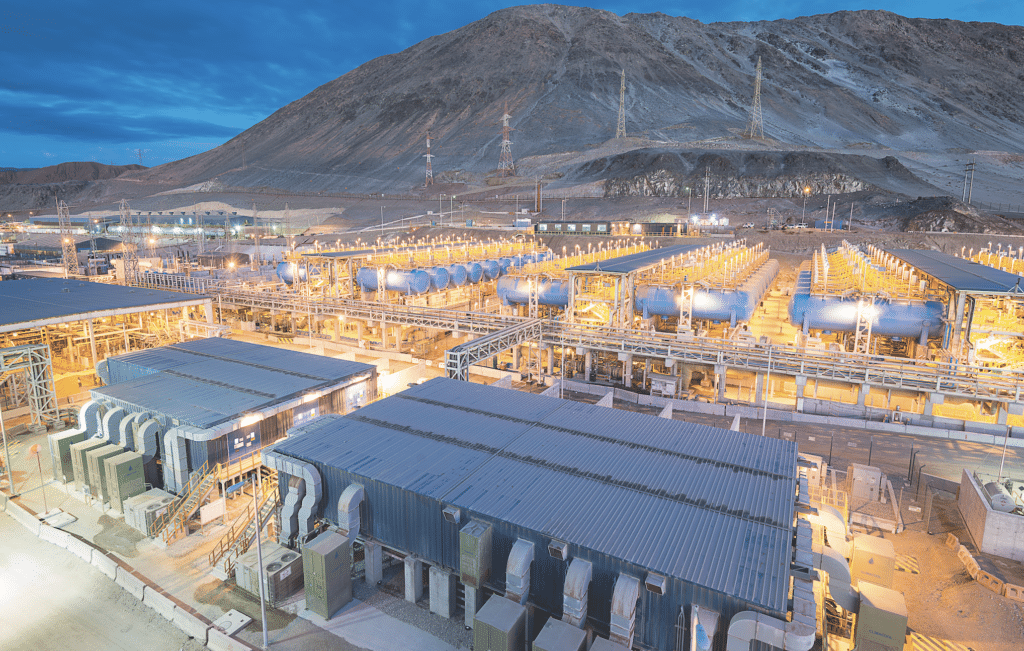

- The Sabah desalination plant in Saudi Arabia uses reverse osmosis and energy recovery technology, with a daily production capacity of 1.5 million tons. It is sufficient to meet the water needs of 2 million residents in the eastern province.

- The Jebel Ali desalination plant in the UAE achieves low-carbon production through a solar power system. And its water supply accounts for 90% of Dubai’s total water consumption, becoming the city’s “water lifeline.”

- Australian mining giant Rio Tinto employs a customized three-stage process of “pretreatment + ultrafiltration + reverse osmosis” to produce desalinated water with a resistivity ≥15MΩ・cm. It meets the high-purity water requirements for iron ore beneficiation. The project is integrated with a mining wastewater recycling system, mixing concentrated brine with beneficiation wastewater to extract rare metals such as lithium and manganese, achieving “multiple uses for one source of water.”

- The Abu Dhabi Taweel desalination project adopts a “low-energy membrane module + differential pressure energy recovery” system and innovatively applies an intelligent membrane fouling early warning system. By using fiber optic sensors inside the membrane to monitor the transmembrane pressure difference and water quality in real time. It can provide early warning of fouling risks 72 hours in advance, extending the membrane life from 3 years to 5 years.

Summarize

From factories on the edge of the Middle East desert to mining facilities in Australia, and water supply systems for islands in my country. Desalination companies are building solid “blue water towers” with technology. Therefore, we believe that with the deepening integration of new materials research and development with new energy sources. Desalinated water will become more economical, environmentally friendly, and efficient.