We launched the reverse osmosis + edi water treatment equipment. Because, in recent years, the demand for pure water in various industries is growing. Different fields have different requirements for pure water quality standards, but the overall trend is to continuously improve the output standards of pure water.

Why recommend EDI water treatment technology?

Because critical processes in the electronics and pharmaceutical industries, such as high-density integrated circuit manufacturing, water for injection, and pharmaceutical water, require stringent control over preparation and testing, and have extremely high standards for the purity and stability of pure water, EDI water treatment technology is employed.

EDI water system not only enables the continuous and stable production of ultrapure water to meet the stringent requirements of high-end industries like electronics and pharmaceuticals, but also avoids the reliance on chemical regeneration in traditional ion exchange processes, achieving a balance between environmental friendliness, cost-effectiveness, and efficiency.

How to produce ultrapure water with EDI water treatment?

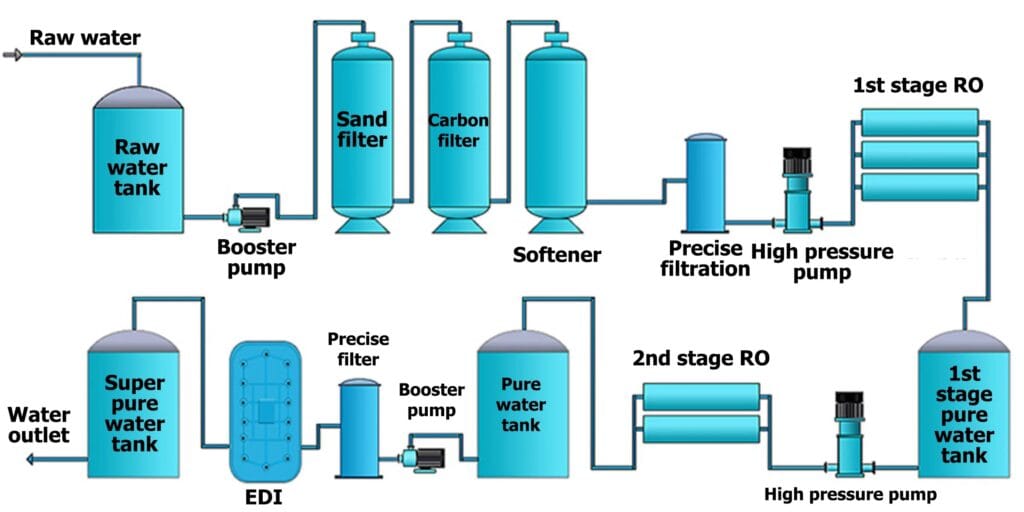

(1) First, the raw water pump will lift the raw water to the filtration system (quartz sand filter tank, activated carbon filter tank, softening resin filter tank) to remove impurities (suspended particulate matter, microorganisms, calcium and magnesium ions) in the water.

(2) After passing through the pretreatment system, the semi-permeable membrane (reverse osmosis membrane, pore size 0.0001-0.001μm) of reverse osmosis technology uses selective permeability to allow water molecules to pass through the membrane under high pressure, while salt ions (such as Na⁺, Cl⁻) and organic matter are retained, resulting in the first pure water.

(3) The primary purified water passes through the secondary reverse osmosis membrane, and the salt content in the purified water is greatly reduced. This method will reduce the conductivity of the water to about 3μS/cm, and the ultrapure water (that) this method prepares can meet the standards for medical water.

What are the advantages of EDI water system?

- High water quality

EDI water system can continuously produce ultrapure water with a conductivity of less than 0.1 μS/cm and a resistivity of up to 18 MΩ·cm. It is suitable for industries with extremely high water quality requirements (such as semiconductors, pharmaceuticals, and power generation).

- Green and environmentally friendly

EDI system relies on a DC electric field to regenerate resin, without the need for chemicals. It is a clean process and is more in line with current environmental regulations and sustainable development needs.

- Continuous and stable operation

Chemical regeneration requires no downtime, ensuring continuous water output and stable water quality.

The system’s modularity, high degree of automation, and simplified operation and maintenance make it suitable for long-term, large-scale operation.

- Low operating costs

Regeneration is less energy-intensive than chemical regeneration, resulting in better long-term economics.

The resin has a long lifespan, requiring less frequent replacement and reducing consumables costs.

The equipment is compact and takes up little space.

In which fields can EDI water treatment equipment be used?

1.Preparation of ultrapure water

Firstly, EDI water treatment system can continuously remove ions and avoid chemical regeneration. The resistivity of the produced water can reach close to 18.2 MΩ·cm (with appropriate pretreatment). Therefore, people use it in situations that demand high water quality stability and low organic/bacterial content, such as the semiconductor, microelectronics, laboratory water, and pharmaceutical industries.

2.Boiler feed water and power plants

Following, power plant boilers are extremely sensitive to ion content and corrosiveness. EDI system is ideal for continuous operation, requires no chemical regeneration, and requires minimal maintenance.

Using a two-stage RO + EDI combined technology to prepare boiler feed water and mitigate the ion load of the EDI feed water, this approach ensures stable operation of the EDI machine and the continuous production of high-quality demineralized water.

3.Lithium recovery, precious metal or heavy metal recovery

We can use EDI methods to selectively enrich and recover metals (lithium, rare metals, and heavy metals) from solutions.

Industries such as electroplating, steel, nonferrous metals, and chemicals generate significant quantities of heavy metal wastewater annually. Discharge of untreated heavy metal wastewater into water or soil can cause permanent damage to the environment and human health. Therefore, heavy metal wastewater must undergo a series of treatment processes to achieve “zero discharge.”

For example, a two-stage integrated EDI water system treats nickel-containing electroplating wastewater. The concentrated water from both stages is partially recycled to recover nickel ions and produce pure water, achieving a nickel ion recovery rate of up to 88.5%.

Obviously, advantages of EDI technology include low operating costs, high ion separation efficiency, and zero secondary pollution. If you have any water treatment needs, please feel free to contact us.

Hubungi kami

Name: Cliff Mok

Mobile phone: +86 17817887719