In rural factories, large-scale farms, and small and medium-sized processing workshops, well water is often an indispensable core production water source. For example, it is used in food factories to clean raw materials, in livestock farms to provide drinking water for livestock, and in machinery factories to cool machines.

However, many operators of large-scale environments fail to realize that the massive water consumption of well water can lead to the rapid accumulation of impurities. And fluctuations in water quality can directly lower product quality. In this case, well water reverse osmosis equipment becomes an effective water treatment solution. It meets both the demand for large volumes of water and ensuring safe and efficient production water.

What problems arise when a large amount of well water is converted into pure water?

Using well water to produce pure water presents several problems, primarily in three areas.

First, it has a high impurity content. Well water, after long-term underground infiltration, carries sediment, colloids, calcium and magnesium ions, and other substances. When equipment operates continuously, these impurities easily adhere to pipes and boiler walls, forming scale. This can reduce heat exchange efficiency and increase electricity costs, or even cause equipment blockage and shutdown.

Second, there is the risk of specific contaminants. If the well water source is near farmland, it may contain pesticide and fertilizer residues. If used in food processing, this will directly lower the probability of product quality.

Third, the water demand is high. Household water purifiers can process a few hundred liters per day. While factories often require several tons or even tens of tons of water, which ordinary water purification equipment simply cannot keep up with.

How does a well water reverse osmosis machine work?

Many people find industrial-grade reverse osmosis (RO) equipment “too technically complex,”. But its core principle is similar to that of household models, just “upgraded to a larger capacity version.” Simply put, well water RO equipment purifies well water through three steps.

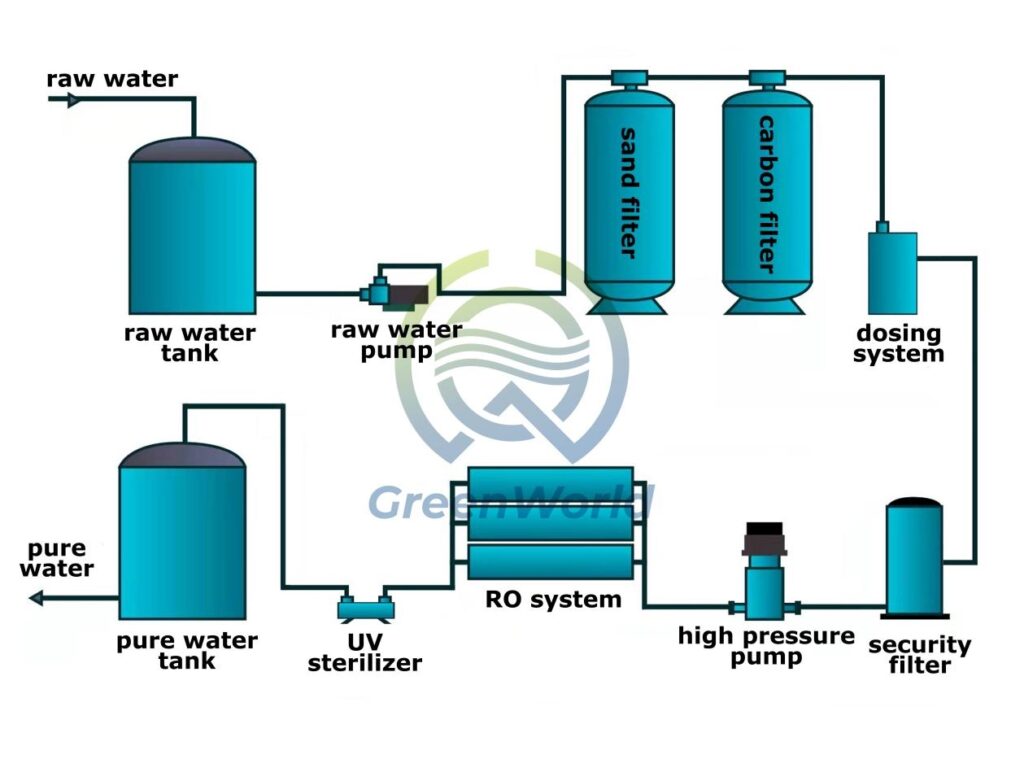

The first step is pre-treatment filtration of the raw water.

A coarse filter removes large particles like sediment and rust, followed by activated carbon to absorb odors and residual chlorine, preventing clogging of core components later.

The second step is reverse osmosis purification.

Industrial-grade equipment uses a wider RO membrane with superior pressure resistance. A high-pressure pump pressurizes the well water, forcing water molecules through the membrane’s “ultra-fine pores.” Heavy metals, bacteria, pesticide residues, and other harmful substances are trapped on the outside of the membrane and discharged through the wastewater outlet.

The third step is post-treatment.

Manufacturers may add minerals or perform disinfection based on factory needs. For example, food factories may further sterilize the water with ultraviolet light to ensure it meets production standards.

What considerations for operating well water reverse osmosis equipment?

However, there are a few things to keep in mind when using well water reverse osmosis equipment.

• First, pre-treatment and filtration of the raw water is essential. Well water contains many impurities, so we must regularly clean the pre-filter screen. Otherwise, the impurities will scratch the reverse osmosis membrane.

• Second, pay attention to wastewater recycling. Although the wastewater generated by the equipment is not directly drinkable. It contains many impurities, so we can collect it and use it for mopping floors, watering green areas, or reuse it in the cooling system.

• Finally, choose the right after-sales service. Equipment problems will affect production schedules, so we need to choose products that suppliers can customize to actual requirements. Ideally, the service should regularly test water quality and remind users to replace filter cartridges to avoid the hassle of “downtime for repairs.”

Summarize

In short, well water reverse osmosis equipment is a practical device specifically designed to solve water shortages and pure water problems. By selecting the right model and performing proper daily maintenance, well water can meet both high-volume demand and production standards, ensuring stable factory operation.

If you also need this type of equipment, please feel free to contact us.