From industrial plants to remote villages, from emergency sites to island development, containerized reverse osmosis machine has built a series of flowing “lifelines” for water quality protection. This innovative equipment, which integrates the entire water purification process into a standard container. And it has completely broken through the bottlenecks of traditional water purification facilities, such as “long construction cycles and large geographical limitations,” and provides customized and efficient water purification solutions for different scenarios.

How does containerized reverse osmosis machine work?

A deep dive into its core technology reveals that the containerized ro machine is a highly intelligent, modular integrated system. Engineers have meticulously designed and optimized each functional unit.

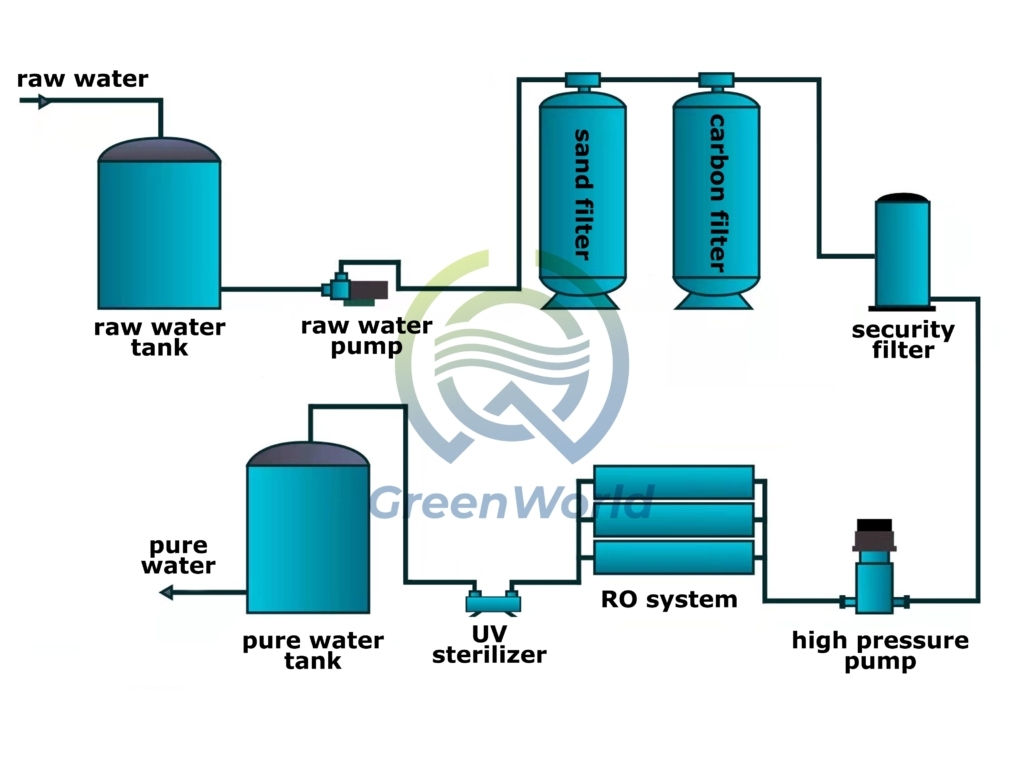

The internal layout typically follows a scientific process: “pretreatment – core purification – deep impurity removal – disinfection and sterilization.”

① Raw water first enters the pretreatment unit, which uses activated carbon, quartz sand, and a water softener to remove large-particle impurities and prevent clogging of subsequent systems.

② We flexibly employ ultrafiltration, reverse osmosis, or nanofiltration membrane systems based on raw water quality.

- For high-turbidity surface water, ultrafiltration membranes are used to remove colloids and microorganisms.

- For brackish water or industrial wastewater, technician uses reverse osmosis membranes to efficiently separate salts and pollutants.

③ Finally, the water passes through an ultraviolet disinfection or ozone sterilization unit to thoroughly kill bacteria, viruses, and other pathogenic microorganisms, ensuring that the effluent meets the “Standards for Drinking Water Quality.”

The entire process is fully automated and monitored by a PLC control system, which adjusts pump pressure and membrane module operating parameters in real time, achieving precise, unattended operation.

Containerized reverse osmosis machine directly address the pain points

Compared to traditional water purification facilities, containerized reverse osmosis machine offers advantages in multiple dimensions, each directly addressing pain points in practical applications.

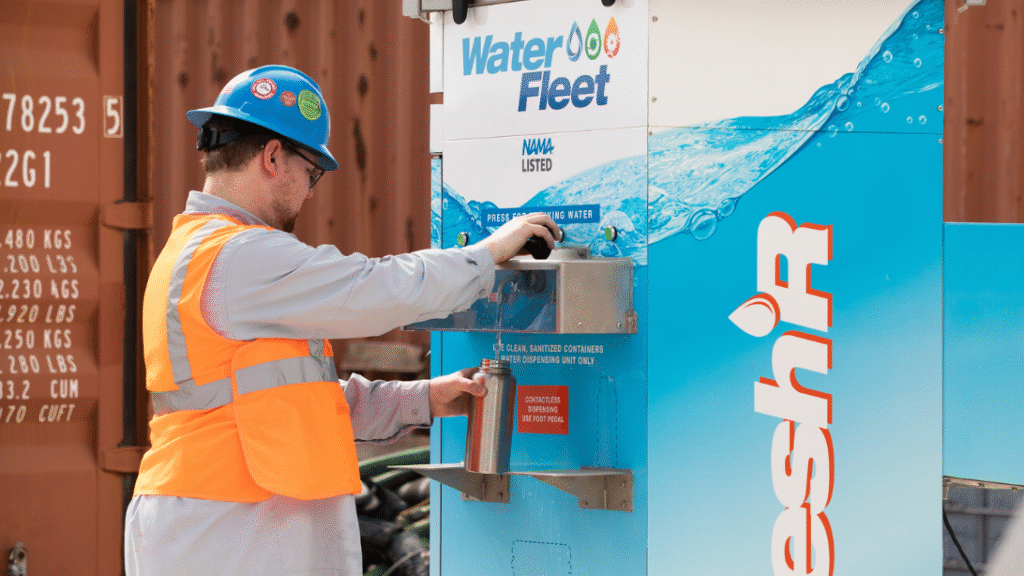

Firstly, it boasts exceptional emergency response capabilities. The standard container size allows for rapid deployment via road, sea, and air transport. Following the 2023 earthquake in Turkey, the EU urgently deployed five containerized water purification units, completing installation and commissioning within 72 hours. These units can treat an average of 1800 cubic meters of wastewater per day. And provide safe drinking water for refugees in the earthquake zone.

Secondly, it boasts significant cost control advantages. Factories prefabricate and commission the equipment in our factory, enabling on-site startup with just pipeline and power connections. This shortens the construction period to 5-12 days, far exceeding the 6-12 month construction period of traditional water treatment plants in Europe and America.

Thirdly, it has an extremely wide range of applications. Treatment capacity can cover 5 to 10,000 tons per day, meeting the wastewater treatment needs of small factories in North America as well as supporting centralized water supply for large villages in Africa.

Extending the application of containerized reverse osmosis machine

Driven by the UN’s “2030 Sustainable Development Goals” initiative to “ensure clean drinking water and sanitation,” the global application scenarios for containerized reverse osmosis machine will continue to expand.

- In agriculture, people have applied this equipment in Israeli desert agricultural areas to treat high-salt irrigation water, boosting tomato yields by 15%, and we export these high-quality tomatoes to Europe.

- In rural water supply, African countries such as Kenya and Tanzania have built more than 300 containerized water purification stations through an “international aid + local operation” model, solving the safe drinking water problem for more than 800,000 rural residents.

- In the emergency response field, users extensively utilize containerized seawater desalination equipment across the Middle East. With its high temperature resistance and sandstorm resistance, it provides a stable supply of fresh water to desert towns.

Data shows that the global market size of containerized water purification equipment exceeded US$12 billion in 2024, with North America and Europe accounting for more than 60% of the market, and the average annual growth rate remained above 28%. It is expected to reach US$23 billion in 2026.

Summarize

Today, containerized reverse osmosis machine has evolved from initial emergency auxiliary equipment into one of the mainstream solutions in the water resource treatment field. Whether ensuring daily water supply or responding to sudden water crises, it safeguards the purity of every drop of water with its flexible, efficient, and reliable characteristics.

If you would like to know the specific configuration parameters and treatment cost calculations of the equipment in a particular scenario, please feel free to ask me. And I will provide you with more accurate information.