The reverse osmosis machine price is not a single value, but a dynamic system affected by multiple variables such as treatment scale, water quality requirements, technical configuration, and brand positioning.

What is the cost ratio of reverse osmosis machine price?

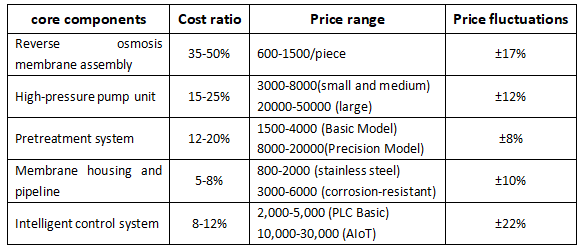

The cost structure of industrial RO machine has a significant “component-dominated” feature, and price fluctuations of upstream core components directly affect terminal quotations.

Therefore, the difference of 역삼투압 기계 price is mainly determined by the processing volume, water quality requirements, membrane technology and degree of automation.

Micro reverse osmosis system (processing capacity < 1 ton/hour)

Price range: $1,200-4,500

Core configuration:

- Membrane assembly: 1-2 4040 reverse osmosis membranes (Times Vorton ULP21-4040), 95-97% desalination rate

- Pump unit: Single-phase high-pressure pump (lift 150-200m), power 0.75-1.5kW

- Control: Manual valve adjustment, basic water quality monitoring (conductivity meter)

- Material: UPVC membrane shell, carbon steel bracket

Price influencing factors:

- Water quality requirements: Resistivity increased from 1MΩ・cm to 10MΩ・cm, price increased by 40%

- Brand premium: Imported brands are 70-100% higher than Chinese brands

- Additional function: if Add automatic flushing function, the price will increase by $350-600

Medium-sized ro systems (5-20 tons/hour)

Price range: $29,000-120,000

Technical features:

- Membrane arrangement: 2-4 segments, 12-40 membranes (mainly 8040 type)

- Energy consumption control: variable frequency high-pressure pump + energy recovery device (small PX unit), energy consumption 1.8-2.5kWh/m³

- Automation: SCADA control system, supporting linkage adjustment of flow, pressure and water quality parameters

- Material: Stainless steel 304/316L pipe, fiberglass/stainless steel membrane housing

Typical project cases:

A juice processing plant’s 15 ton/hour system, using Dow anti-fouling membranes and Grundfos variable speed pumps, including a CIP cleaning system, was quoted at NT$52,300, with annual maintenance costs of NT$4,800 (membrane replacement cycle is three years).

An industrial park’s reclaimed water reuse project, using OriginWater’s MBR-RO coupled process, boasts an 85% recovery rate and a quoted price of NT$89,600. The company received a 20% local environmental protection subsidy of NT$17,920.

Large reverse osmosis machine (processing capacity 20-100 tons/hour)

Price range: $125,000-450,000

- Membrane system: 8040 membrane modules (40-120 units), using low-energy membranes (Dow SW30XHR-440i), with a desalination rate of over 99.5%

- Pump unit: Large multi-stage centrifugal pump (22-75kW), efficiency ≥85%, some equipped with magnetic bearing technology

- Energy recovery: PX or DWEER energy recovery device, reducing energy consumption to 1.2-1.8kWh/m³

- Control: Distributed control system (DCS) with integrated AI predictive maintenance module

Application scenarios:

Power Industry (Boiler Feed Water): 50 tons/hour capacity, resistivity ≥ 5 MΩ・cm, silicon content < 20 ppb. Total price: 320,000 (Kaiquan pump + Wharton membrane). Imported configuration (Ebara pump + Dow membrane) quoted at 425,000.

Refinery catalytic cracking wastewater reuse project: 80 tons/hour capacity, 80% recovery rate, quoted at $382,000, payback period 2.8 years.

Electronics and Semiconductors (Ultrapure Water Pretreatment): 30 tons/hour capacity, resistivity ≥ 10 MΩ・cm, particle count < 1 particle/mL. Total price: 375,000, Veolia quoted at $480,000.

Factors that affect the difference of reverse osmosis machine price

Membrane Brands

Dow and Toray reverse osmosis systems are more expensive, but offer a 30% longer lifespan. For example, the Dow 8040 membrane element costs $245-265 per unit.

Pretreatment Complexity

High-hardness raw water requires the addition of a softener and sand filter, increasing costs by $2,000-$5,000.

Desalination projects require safety filters and antiscalant dosing systems, increasing overall system costs by 30%.

Automation and Intelligence

Basic manual control equipment is 25-30% cheaper than fully automated PLC systems.

Intelligent systems with integrated AI algorithms (such as Dow iAdaptive™) can reduce manual maintenance costs by 50%, but carry a 20% price premium.

Energy Consumption and Environmental Standards

The EU Carbon Border Adjustment Mechanism (CBAM) requires that new RO projects after 2025 consume ≤2.1 kWh/m³ of energy. This will force companies to adopt energy-saving equipment such as magnetic levitation pumps, increasing costs by 15%.

Procurement Recommendations

Technology Upgrade Directions

① Energy Saving: Graphene-based composite membranes have demonstrated laboratory efficiency three times that of commercial membranes, and mass production is expected in 2028.

② Modularization: Demand for containerized mobile RO systems (such as the Suez Smart Shelter) is surging in the Middle East and African markets, with unit prices ranging from $12,000 to $25,000.

Procurement Cost Optimization Strategies

① Selecting cost-effective membrane alternatives: Chinese reverse osmosis membrane companies such as Wharton and Huitong hold over 40% market share in the power and metallurgical sectors, offering significant cost-performance advantages.

② Lifecycle Cost: While high-priced equipment (such as EDI systems) has a high initial investment, annual maintenance costs are 40% lower than basic models.

③ Policy Benefits: The EU provides green credit interest subsidies for low-carbon RO systems.

Risk Mitigation Points

Water Quality Testing: High-pressure RO (HPRO) is required when raw water TDS exceeds 5,000 ppm; otherwise, membrane life is shortened by 50%. Supplier qualifications: Give priority to manufacturers that have passed ISO and CE certification to avoid frequent failures caused by low-priced “three-no” equipment.

요약

Reverse osmosis machine prices actually range from thousands to millions of dollars, primarily driven by factors like water quality stability, energy efficiency, and long-term operation and maintenance costs. For small and medium-sized businesses, a basic or two-stage RO system priced between $10,000 and $30,000 is sufficient. High-value-added industries like semiconductors and chemicals, however, require investments in EDI systems exceeding $50,000.

In the 2025 market, intelligent and energy-saving technologies will become mainstream. We must balance our needs with policy guidance to find the optimal balance between performance and cost.

If you require a 역삼투압 기계 quote, please feel free to contact us.