Automatic Packing Machine

Including water treatment equipment and engineering projects,adhere to the business philosophy of high quality and good service,fully meet customer needs,provide customers with advanced equipment,fundamentally solve customer problems,and create the greatest value for customer.

Automatic Packing Machine

It can automatically sterilize with ultravilet rays,automatically back-sealing material bag forming,quantitative filling,sealing and cutting at one time,and print the count date.

| Desalting Rate | More than 97% |

| Water Recovery | About 50-65% |

| Voltage | 220v 380V 50HZ 60HZ(Or Customized) |

| RO membrane | DOW Membrane USA Original Vontron |

| High pressure pump | CNP |

| Raw water pump | Lingxiao |

| Filter Media | Sand+Carbon+Softener |

| Certification | CE ISO |

Product Details

XinJieYuan’s automatic packing machine is the final step in the water filling line, specifically designed to package pure water liquids into bags.

It automatically performs the corresponding sealing operations for the common bottled or bagged packaging of water products. We can seal bottled water with screw caps or press caps, while manufacturers use heat-sealing technology to securely seal the openings of bagged water. This sealing method completely isolates the water from air and dust, prevents water leakage and secondary contamination, and ensures cleanliness during the storage and transportation of the water.

This equipment not only efficiently seals purified and pure water products into bags or bottles after prior purification and filling processes. But also simultaneously prints information such as production date and batch number. Therefore, we can sell packaged water to communities, supermarkets, airports, wholesale markets, and other diverse environments.

How do automatic packing machine work?

1. Material transportation

Firstly, the products to be packaged are automatically transported to the water filling position via a conveyor belt.

2. Measuring/Filling

Secondly, automated design accurately controls the amount of material used and fills it into packaging containers (such as bags, boxes, bottles, etc.). So, enterprises commonly use it in the beverage, dairy, mineral water, and packaged water industries.

3.Container forming/supply

Thirdly, the equipment automatically supplies pre-made containers (such as glass bottles, plastic bottles, bags (composite film bags) packaging).

4. Sealing

Finally, the packaging container is sealed by heat sealing, pressure sealing, screw capping, labeling, etc. to prevent leakage, moisture or deterioration of the material (such as the heat sealing edge of bagged snacks and the screw capping of bottled beverages).

How do automatic packing machine look like?

What are the advantages of automatic packing machine?

1. High Efficiency

It can package dozens to hundreds of products per minute, far exceeding manual labor.

2. Accurate Precision

Measuring errors are controlled within ±1%. So, eliminating the “overfilling” and “underfilling” issues often associated with manual filling.

3. Hygiene and Safety

We make product-contacting components of stainless steel and equip them with integrated disinfection, which reduces the risk of contamination from manual contact (especially suitable for food and pharmaceutical products).

4. Cost Reduction

Long-term use can replace multiple packaging workers, reducing labor, management, and training costs.

5. Simultaneous Information Coding

Automatically prints the production date, expiration date, batch number, and anti-counterfeiting code on the packaging surface according to the food and beverage industry compliance requirements.

6. User-Friendly

The device utilizes a visual human-machine interface (touchscreen operation with graphical guidance). In other words, no specialized technicians are required. Ordinary workers can operate it independently after 1-2 hours of training.

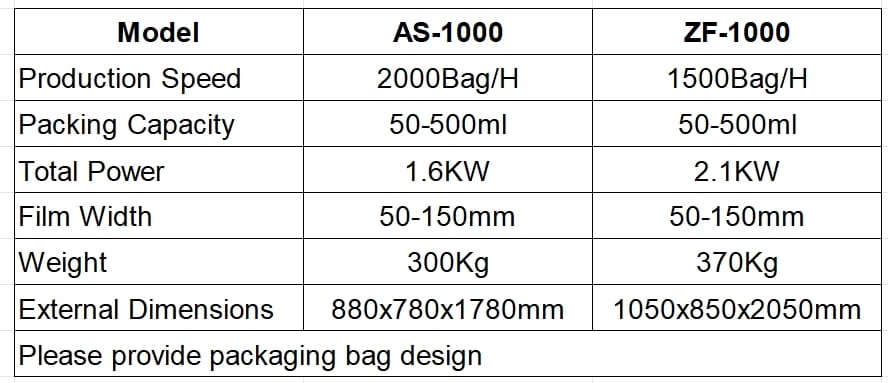

What specifications can be provided?

OUR FACTORY

WORKSHOPS

Guangdong Xinyuanyuan Environmental Protection Technology Co., Ltd., founded in 2018, is an integrated environmental enterprise specializing in scientific research, production and sales, boasting a professional team of 20 to 99 members and a well-equipped facility spanning approximately 1,800 square meters at Panyu District, Guangzhou, China. Strategically situated in the core of the Pearl River Delta, the company leverages its prime location to support efficient operations, expand business across agriculture, chemical engineering, medical care and food processing industries (covering environmental equipment R&D, water/sludge treatment and ecological restoration), and facilitate seamless import-export operations for global clients.

FAQ

We customize equipment parameters and treatment solutions based on your water need (such as water quality, voltage, process, etc.), and all products comply with international universal standards (including ISO, CE, etc.) with complete certification documents. From equipment selection and installation guidance to post-sales maintenance, our professional technical team offers full-cycle support. Leveraging our global cooperative logistics network, we ensure fast delivery with an after-sales response time of no more than 24 hours, fully resolving any concerns you may have during overseas procurement and usage.