Water Filling Machine

Including water treatment equipment and engineering projects,adhere to the business philosophy of high quality and good service,fully meet customer needs,provide customers with advanced equipment,fundamentally solve customer problems,and create the greatest value for customer.

Water Filling Machine

It is an automated or semi-automated production line that performs a series of operations such as filling, sealing, labeling and packaging on treated water.

| Desalting Rate | More than 97% |

| Water Recovery | About 50-65% |

| Voltage | 220v 380V 50HZ 60HZ(Or Customized) |

| RO membrane | DOW Membrane USA Original Vontron |

| High pressure pump | CNP |

| Raw water pump | Lingxiao |

| Filter Media | Sand+Carbon+Softener |

| Certification | CE ISO |

Product Details

The water filling machine RO treats source water or other liquids, fills the treated ones into designated bag containers, and lastly completes automatic packaging.

The water filling machine assembly line integrates water treatment and filling functions. In terms of water treatment, we remove suspended particles through pretreatment system, then use ion exchange resins to soften water. And ultraviolet rays, ozone or chlorine disinfection is used to sterilize and disinfect. Another terms of filling function, it adapts to various packaging forms and has high-speed filling capabilities.

How do water filling machine work?

The water filling machine assembly line integrates water treatment and filling functions. We remove suspended particles through the pretreatment system and use ultraviolet rays, ozone or chlorine disinfection to sterilize and disinfect.

1.Raw water pretreatment:

First, the raw water undergoes a series of pretreatment steps, such as filtration and sedimentation, to remove large particles. Thus, provide a relatively clean water source for subsequent deep treatment.

2.Deep water treatment:

Then, the raw water enters the deep water treatment stage, usually using RO (reverse osmosis) technology. RO membranes can effectively intercept impurities such as soluble salts, organic matter, bacteria, viruses, etc. in the water, thereby obtaining high-quality pure water.

3.Water quality improvement and regulation:

After obtaining pure water, we need to further improve water quality, such as increasing the oxygen content in the water to enhance its taste and activity. as needed, we can also adjust the water’s pH value, hardness and other parameters to meet the requirements of specific products.

4.Purified water storage and distribution:

Additionally, we store pure water after deep treatment and water quality improvement in a dedicated stainless steel water storage tank to ensure that the water quality is not polluted by the outside world. According to production needs, we can transport purified water to the filling area through a pipeline system.

5.Filling and sealing:

Finally, in the filling area, we accurately fill purified water into various containers, such as bottles, bags and barrels. During the filling process, the machine automatically completes container positioning, filling, sealing and other operations to ensure that each container contains a specified amount of purified water and is firmly sealed without leakage.

How do water filling machine look like?

What are the advantages of water filling machine?

1.Integrated process

From raw water storage, treatment, water quality improvement to filling and sealing, we highly integrate the entire process to form a complete water filling machine.

2.Efficient treatment

Adopting advanced RO (reverse osmosis) water treatment technology, it can efficiently remove impurities, microorganisms and harmful substances in water to ensure pure water quality.

3.Water quality improvement

Equipped with an oxygen generator to increase the oxygen content in the water, improve the taste and activity of the water, and make the water more fresh and delicious.

4.Diversified packaging

Supports various types of water bag packaging to meet the needs of different consumers.

5.Automated production

Liquid filling and sealing machine realizes automated filling and sealing operations, improves production efficiency and reduces manual intervention.

6.Product diversification

Supports multiple packaging types, can meet the needs of different markets and consumers, and improve the market competitiveness of products.

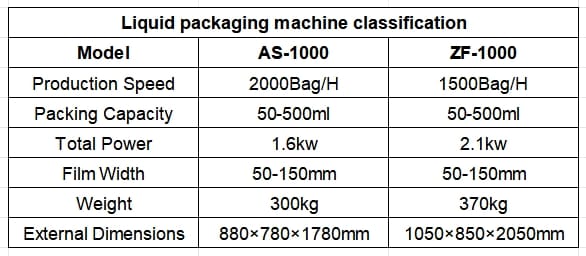

What specifications can be provided?

OUR FACTORY

WORKSHOPS

Guangdong Xinyuanyuan Environmental Protection Technology Co., Ltd., founded in 2018, is an integrated environmental enterprise specializing in scientific research, production and sales, boasting a professional team of 20 to 99 members and a well-equipped facility spanning approximately 1,800 square meters at Panyu District, Guangzhou, China. Strategically situated in the core of the Pearl River Delta, the company leverages its prime location to support efficient operations, expand business across agriculture, chemical engineering, medical care and food processing industries (covering environmental equipment R&D, water/sludge treatment and ecological restoration), and facilitate seamless import-export operations for global clients.

FAQ

We customize equipment parameters and treatment solutions based on your water need (such as water quality, voltage, process, etc.), and all products comply with international universal standards (including ISO, CE, etc.) with complete certification documents. From equipment selection and installation guidance to post-sales maintenance, our professional technical team offers full-cycle support. Leveraging our global cooperative logistics network, we ensure fast delivery with an after-sales response time of no more than 24 hours, fully resolving any concerns you may have during overseas procurement and usage.