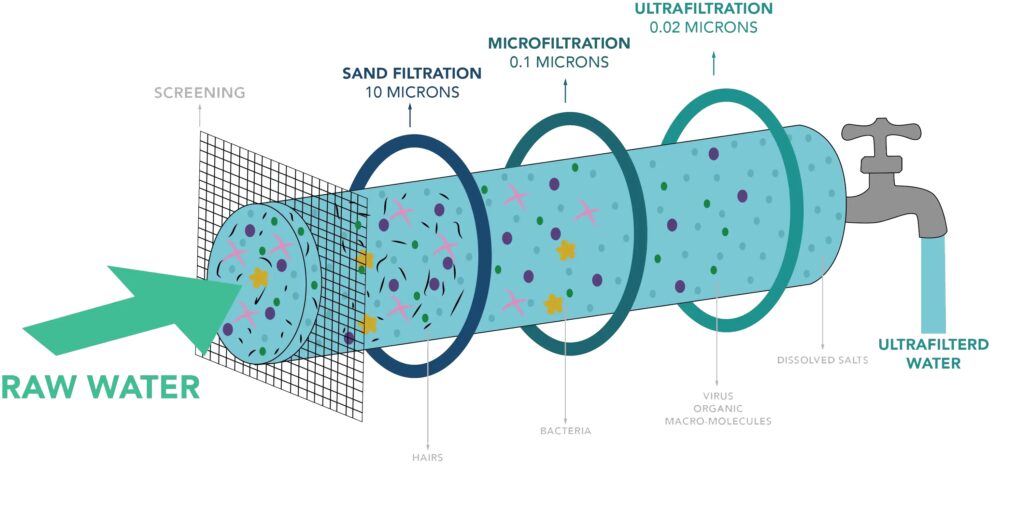

In numerous industrial applications, such as industrial production, water treatment, and biomedicine, ultrafiltration unit, with its core ultrafiltration membrane, acts as a pressure-driven separation tool, precisely trapping macromolecules and colloidal particles while allowing small molecules and solvents to pass through smoothly, providing efficient and environmentally friendly solutions for processes such as production purification and water purification.

How does an ultrafiltration unit work?

Ultrafiltration machine utilizes an ultrafiltration membrane as the primary separation medium. Under external pressure, the material to be treated flows through the surface of the ultrafiltration membrane. The membrane retains large molecules with diameters exceeding its pore size—such as proteins, polysaccharides, colloidal particles, and suspended solids—on its surface, forming a concentrate. Small molecules, such as water molecules and inorganic salts, can pass through the membrane’s micropores, forming the permeate, thus achieving material separation and purification.

Compared to traditional filtration technologies, ultrafiltration unit operates at a more moderate pressure, typically between 0.1 and 0.5 MPa, eliminating the need for extreme conditions such as high temperature and high pressure. This not only prevents the target substance from altering its properties due to extreme environments. But also reduce the equipment’s energy consumption.

What is an ultrafiltration membrane?

Ultrafiltration membranes are pressure-driven membrane separation materials with a uniform and controllable microporous structure. They not only retain large molecules in water or materials but also allow small organic molecules to pass through.

The asymmetric structural design of ultrafiltration membranes ensures separation efficiency while reducing the accumulation of contaminants on the membrane surface, thereby extending the membrane’s lifespan.

What are the components of an ultrafiltration unit?

A complete ultrafiltration device consists of multiple key components working together, and its core components mainly include the following categories:

Ultrafiltration Membrane Modules:

Based on their structure, they can be divided into four types: hollow fiber, spiral wound, tubular, and plate. Enterprises often use hollow fiber ultrafiltration membrane modules in large – scale water treatment and industrial separation applications, as these modules boast advantages like large membrane area per unit volume, compact structure, and low cost.

Pressure and Delivery System:

Mainly composed of a pressure pump, pipelines, and valves, this system is responsible for providing stable pressure for material flow and the membrane separation process. The selection of the pressure pump needs to be based on the equipment’s throughput and the pressure requirements of the membrane module to ensure that the material passes through the ultrafiltration membrane at a stable flow rate, avoiding pressure fluctuations that could affect the separation effect.

Cleaning and Regeneration System:

After prolonged operation, contaminants accumulate on the membrane surface, leading to a decrease in membrane flux. The cleaning system removes contaminants from the membrane surface and restores the membrane’s separation performance through a combination of chemical cleaning (such as acid and alkali solutions, oxidants, etc.) and physical cleaning (such as backwashing, air washing).

Control System:

Modern ultrafiltration unit is generally equipped with an automated control system. These systems utilize sensors to monitor key parameters such as feed flow, pressure, and temperature in real time, and automatically adjust the equipment’s operating status.

For example, when the membrane flux drops to a preset critical value, the system automatically triggers a cleaning procedure. If the sensor of the equipment detects abnormal pressure, the equipment will issue an alarm and stop operating, ensuring the safety and stability of the device.

Ultrafiltration unit is widely used in the following fields

Water Treatment:

- In drinking water purification, ultrafiltration unit effectively removes bacteria, viruses, algae, and suspended solids from water. And it replaces traditional sedimentation tanks and sand filters, and eliminating the need for disinfectants.

- In industrial wastewater treatment, it can pre-treat and deeply treat wastewater from industries. Such as printing and dyeing, chemicals, and electroplating, retaining large molecular pollutants and heavy metals.

Food and Beverage Industry:

- In dairy processing, ultrafiltration eunit separates casein and whey protein from milk, improving the purity and value of dairy products.

- In fruit juice production, it removes impurities such as pectin and cellulose. Thus it will improve the clarity and stability of the juice while retaining nutrients and flavor components.

- In the brewing industry, breweries use an ultrafiltration system for the clarification filtration of wine and beer. Then it reduces sedimentation and extending the product’s shelf life.

Biomedical Field:

- Ultrafiltration machine is suitable for the separation and purification of biological products such as antibiotics, vaccines, and proteins. For example, in protein purification, ultrafiltration can remove small molecule impurities and salts from the solution. Therefore achieve protein concentration and purification while preserving the function of bioactive substances.

Other fields:

- In the electronics industry, manufacturers use ultrafiltration machines to produce ultrapure water, supplying a high-purity water source for semiconductor chip manufacturing.

- In the textile industry, ultrafiltration system can recycle and treat dyeing wastewater, enabling the recycling and reuse of dyes and water, thus reducing the industry’s environmental burden.

Summarize

Ultrafiltration unit can precisely separate substances of different molecular weights, achieving separation results far superior to traditional filtration technologies. Its operation is environmentally friendly, requiring no large amounts of chemical reagents, thus reducing secondary pollution. In the future, ultrafiltration membranes will become more precise, more resistant to fouling, and have a longer lifespan. The combined application of ultrafiltration technology with other separation technologies. For example, reverse osmosis and nanofiltration will become more mature, meeting more complex separation needs.

If you also need this equipment, please feel free to contact us.