In fields with extremely stringent water quality requirements, such as semiconductor manufacturing, biopharmaceuticals, and laboratories, ultra pure water purification system has become indispensable core equipment. Therefore, through the coordinated action of these system modules, impurities are separated from ordinary tap water or industrial water to produce ultrapure water with extremely high purity.

What is ultra pure water?

The term “ultra pure water” typically refers to high-purity water with a resistivity of 18.2 MΩ·cm, total organic carbon content below 10 ppb, and particulate matter content close to zero.

What is its purpose of ultra pure water purification system?

First, in the chip manufacturing industry, ultra pure water eliminates interference from impurities, ensuring circuit performance.

Second, in the pharmaceutical field, it directly impacts drug quality and patient health, necessitating the avoidance of water contamination risks and compliance with safety standards.

Third, in precision experiments, ultra pure water eliminates background interference, guaranteeing reliable results.

Last, in new energy fields such as photovoltaics and lithium batteries, ultra pure water ensures material purity and optimizes product performance.

How does an ultra pure water purification system work?

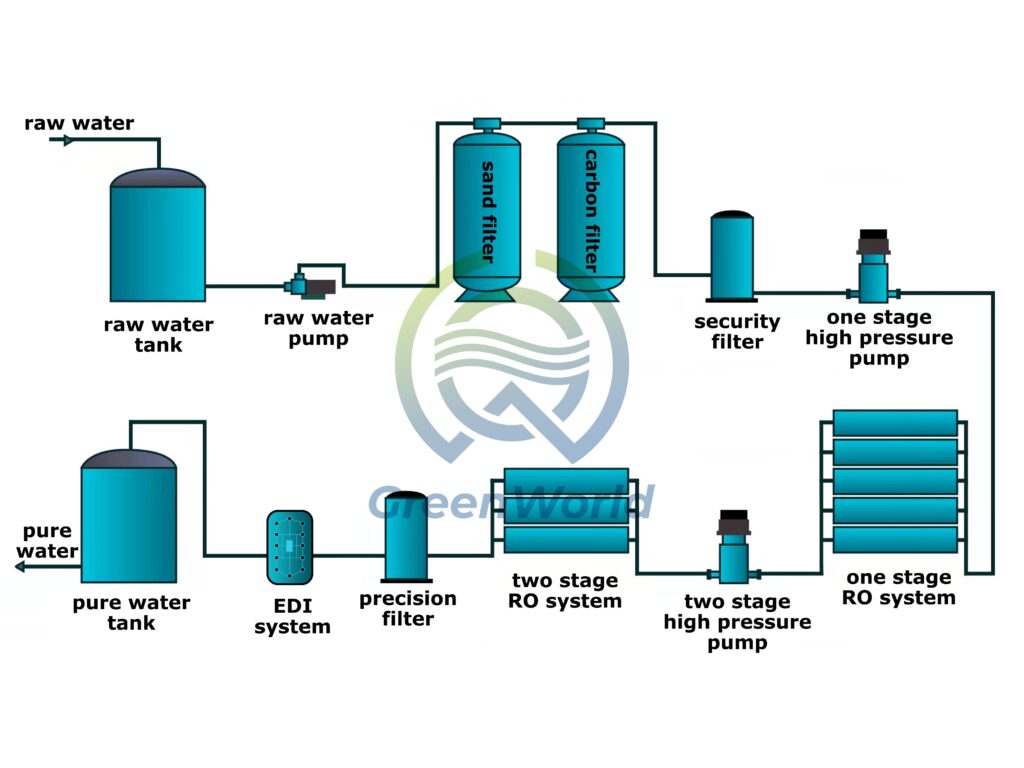

Ultra pure water purification system removes various pollutants from water through a combination of multiple processes, mainly including the following key water treatment steps.

- Preprocessing system

The purpose of pretreatment is primarily to remove suspended solids, colloids, residual chlorine, hardness ions, etc. from the raw water. Processes such as quartz sand filtration, activated carbon adsorption, and softening resin exchange reduce the load on subsequent advanced treatment processes and prevent membrane module clogging or damage.

- Deep desalination technology

This process uses reverse osmosis + EDI technology to remove over 99% of ions from the water.

Reverse osmosis membranes utilize pressure difference to separate salts from water molecules, achieving a desalination rate of over 99.5%, making it the most economical and efficient desalination method currently available.

EDI technology combines electrodialysis and ion exchange, eliminating the need for chemical regeneration and enabling the continuous and stable production of high-purity water.

- Terminal Refining Process

To meet water quality requirements in extreme scenarios, the terminal needs to remove residual microorganisms, particulate matter, and trace ions through ultraviolet (UV) sterilization or ozone processes.

What are the standards for measuring ultrapure water?

Key performance indicators for ultrapure water purification systems include:

Resistivity: Reflects the ion content in the water; 18.2 MΩ·cm (25℃) is the theoretical maximum.

Total Organic Carbon (TOC): Reflects the content of organic pollutants; high-end applications require levels below 1-5 ppb.

Particulate Count: The number of particles larger than a specific size (e.g., 0.1 μm) per unit volume.

Microbial Content: Must be controlled below 1 CFU/mL; sterility is required in some scenarios.

Development Trends of Ultra Pure Water Purification System

The global ultrapure water purification machine market is worth approximately US$30 billion and has long been dominated by international giants (such as Pall Corporation of the United States, Siemens of Germany, and Asahi Kasei of Japan).

Chinese companies, on the other hand, dominate the low-to-mid-end market (such as photovoltaics and conventional pharmaceuticals), with a domestic market share reaching 58% by 2025.

1. Breakthrough Directions for Chinese Enterprises

High-end Market Penetration

Targeting the needs of semiconductor 12-inch and larger wafer fabs, some companies, in collaboration with major universities, have developed “low-metal leaching systems,” which have already entered the supplier systems of SMIC and Hua Hong Semiconductor.

Service Model Innovation: Some companies have launched “ultra pure water system leasing + operation and maintenance services,” eliminating the need for upfront equipment costs and allowing payment based on water consumption, thus lowering the entry barrier for small and medium-sized customers.

Green Technology Export: Many companies have already promoted “high-recovery-rate concentrate treatment technology” to water-scarce regions such as Southeast Asia and the Middle East.

2. Future Competitive Focus

International giants have launched systems with “carbon emissions of less than 10 kg CO₂/m³ throughout the entire life cycle”, while Chinese companies are striving to reduce the carbon emissions of their systems to below 8 kg CO₂/m³ by 2026 through a combination of “photovoltaic power supply + waste heat recovery”.

Summarize

Chinese companies are gradually transforming from “equipment suppliers” to “full-scenario solution providers.” In the future, with the international upgrading of industries such as semiconductors and new energy, ultra pure water purification system will usher in a dual opportunity of “technological iteration + market expansion,” providing solid support for the sustainable development of high-end manufacturing.

If you are also interested in customizing such a system, please feel free to contact us.