As an advanced membrane separation technology, large reverse osmosis system plays an important role in seawater desalination. Due to their high efficiency, energy saving, and stability. These systems produce large quantities of high-quality water by removing pollutants and dissolved solids.

What is a large reverse osmosis system?

Large reverse osmosis system uses reverse osmosis technology to produce pure water. The core of RO technology lies in the magical properties of its semi-permeable membranes. The pores of these membranes are only 0.1 nanometers. Thus, it is equivalent to one millionth of the diameter of a human hair. Under high pressure, water molecules not only can pass through these micropores, but more than 99% of dissolved salts, minerals and microorganisms are effectively intercepted.

Components of large reverse osmosis system

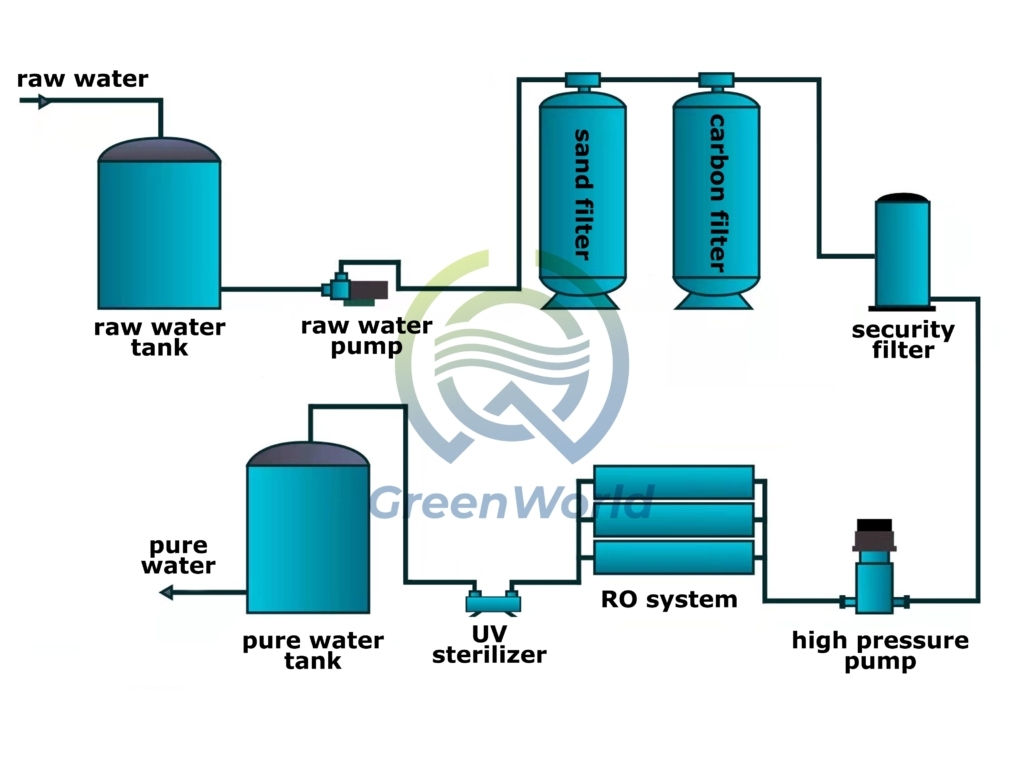

Large reverse osmosis system consists of various components that work together to ensure efficient water treatment. These components include the pre-treatment system, the reverse osmosis unit, the storage and distribution unit, the post-treatment system, and the instrumentation used to monitor water quality.

1.pretreatment system

Pretreatment is a key step in the reverse osmosis process. It can prevent membrane fouling and improve the overall efficiency of the system. First, the pretreatment system usually includes

- lMultimedia filter: Removes large particles from the feed water to ensure the operation of the reverse osmosis membrane.

- lCarbon filter:Eliminates chlorine, organic compounds and other contaminants that may damage the membrane.

- lWater softener:In hard water areas, a water softener is used to remove minerals such as calcium and magnesium.

- lUltraviolet disinfector:RO systems kill bacteria, viruses and other microorganisms that may be present in the feed water to protect the reverse osmosis membrane.

2.reverse osmosis process

Secondly, we use Huitong reverse osmosis membranes to form the unit to remove dissolved solids and contaminants from water. This reverse osmosis unit is designed to treat large volumes of water, making it ideal for industrial applications.

3.storage and distribution

Thirdly, due to the slow water production rate in the RO process, operators or relevant systems require a water storage tank to store the purified water. Therefore, we in the related field commonly use two types of water storage tanks: atmospheric water storage tanks and bladder water storage tanks. To distribute the water, operators or systems also require a re-pressurization pump to ensure a steady flow of water.

Although the atmospheric water storage tank is larger in size, it produces higher quality water. Because there is no bladder water storage tank. The bladder water storage tank is more compact and is therefore more suitable for small systems.

4.post-treatment system

Additionally, post-treatment is an important step to improve the quality and stability of purified water. Common post-treatment methods include

- lpH adjustment:Raise or lower the pH of water to the desired level to optimize subsequent processes.

- lDeionization:Remove residual ions and minerals in water to produce ultrapure water suitable for laboratory use or special applications such as semiconductor manufacturing.

- lUltraviolet disinfection:Use ultraviolet light to eliminate residual bacteria, viruses or microorganisms in water to ensure the microbiological safety of water.

5.monitoring water quality

Finally, to monitor and maintain the quality of purified water, a variety of instruments and analyzers are used. These instruments can measure parameters such as pH, conductivity and temperature, providing real-time data for process control and adjustment.

Typical cases of large reverse osmosis system

Singapore NEWater Project

- Application Background: Singapore, a water-scarce country, uses a large reverse osmosis system to deeply treat urban sewage into industrial water and drinking water sources, with an annual treatment volume of hundreds of millions of cubic meters.

- System scale:The number of RO membrane modules in a single treatment plant exceeds 100,000, and the daily treatment capacity exceeds 100,000 tons.

Samsung Pyeongtaek Chip Factory in South Korea

- Application scenario:Samsung Pyeongtaek Factory produces 3nm chips, and its RO system is one of the world’s largest semiconductor water treatment projects.

- System parameters:

- Daily processing capacity of 80,000 tons, using the “three-level RO+EDI” process, the outlet water resistivity is stable at 18.2MΩ・cm (close to theoretical pure water).

- Equipped with German Koch membrane elements, the anti-silicon pollution design avoids impurity deposition on the wafer surface, and the yield is increased to 98%.

Maersk container ship

- Compliance requirements:

- The International Maritime Organization (IMO) has formulated new regulations in 2025 that require all ship ballast water to undergo RO treatment to kill microorganisms.

- System configuration:

- Maersk’s team has equipped its 18,000 TEU container ship with a German WesTech RO system—one that features a processing capacity of 2000m³/hour and hollow fiber membrane modules.

- After RO treatment, the microbial concentration of ballast water is less than 10/m³, which meets the D-2 standard, and the system occupies only 150㎡.

Challenges and prospects of large reverse osmosis system

Although people have developed the technology of large reverse osmosis systems to a relatively mature level. This technology still faces many technical challenges, such as membrane fouling. Biological fouling, scaling and colloidal fouling will significantly reduce the efficiency of the system. In terms of brine treatment, the environmental impact of high-salinity discharge water needs to be properly addressed. In terms of energy consumption, although the efficiency has improved, it still accounts for 30-50% of the operating cost.

People expect that with technological progress and economies of scale, by 2030, the global reverse osmosis desalination capacity will increase by 40%. The unit energy consumption will see a further reduction of 20-30%. The level of intelligence will improve significantly, and its combination with renewable energy will become closer.

The giant reverse osmosis system is not only an engineering and technological achievement, but also an important weapon that people can use to cope with water resource challenges. If you have any water treatment problems, you can always consult “https://xjyco.com/” to solve your confusion.

Contact us

Name: Cliff Mok

Mobile phone: +86 17817887719