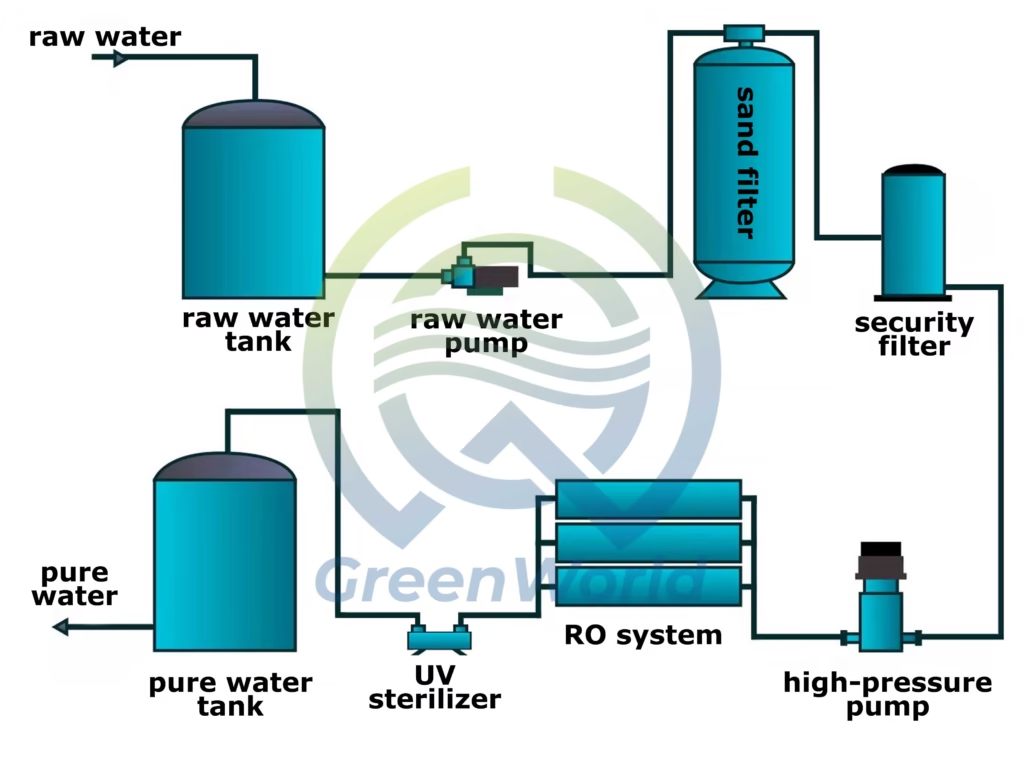

A reverse osmosis skid machine integrates the reverse osmosis core filtration system, pretreatment systems (such as multi-media filtration and activated carbon filtration), post-treatment units (such as ultraviolet disinfection), pipeline valves, control systems, and auxiliary equipment (such as high-pressure pumps and water storage tanks) into a standardized container.

This system actually utilizes the selective permeability of the reverse osmosis membrane. To retain impurities such as inorganic salts, organic matter, colloidal particles, and microorganisms in water at an operating pressure higher than the osmotic pressure of the solution. Then producd purified water that meets industrial or municipal water standards.

This system actually utilizes the selective permeability of the reverse osmosis membrane. To retain impurities such as inorganic salts, organic matter, colloidal particles, and microorganisms in water at an operating pressure higher than the osmotic pressure of the solution. Then producd purified water that meets industrial or municipal water standards.

1. Preprocessing module

- Multi-media filter: uses quartz sand to intercept suspended solids (SS) in the influent water ≤10mg/L, with a filtration accuracy of 5-10μm, equipped with an automatic backwash function, and a backwash cycle of 12-24h.

- Activated carbon filter: Filled with columnar granular activated carbon, it absorbs residual chlorine (≤0.1mg/L), organic matter, and odor in the water, protecting the reverse osmosis membrane from oxidative damage. The filter material replacement cycle is 6-12 months.

- Security filter: PP melt-blown filter element with a precision of 1μm, intercepts tiny particles remaining after pretreatment to prevent clogging of the reverse osmosis membrane. The filter element replacement cycle is 15-30 days.

2. Reverse osmosis core module

- Membrane elements: Use industrial-grade 8-inch reverse osmosis membranes (such as Dow BW30-4040 and HydraNergy CPA3-LD). A single membrane element has a water output of 1.5-2.0 m³/h and a desalination rate of ≥99.5%.

- Membrane housing: Made of FRP (Fiberglass Reinforced Plastic)/304 stainless steel, with a pressure rating of 2.0 MPa. Each membrane housing houses 6-8 membrane elements, forming a 4-8 segment membrane array.

- High-pressure system: Equipped with a stainless steel variable-frequency high-pressure pump (flow-adaptive membrane system, head 150-200m), with a pressure sensor and safety valve to prevent system damage from overpressure.

3. Post-processing module

- Ultraviolet sterilizer: uses ultraviolet lamps with a wavelength of 254nm, with a sterilization rate of ≥99.99%, inactivating microorganisms such as E. coli and Legionella, meeting the hygiene standards for drinking water or industrial circulating water.

- Water storage and delivery: Equipped with a water storage tank (with a capacity of 1-2 times the hourly water production) and a variable frequency water supply pump to ensure stable water delivery to the water consumption point.

4. Control system

- Core controller: uses a PLC (such as Siemens S7-1200) with a 10-15 inch touch screen to enable parameter setting and function selection.

- Automatic protection function: It has high-pressure pump water shortage protection, membrane system overpressure protection, inlet water quality exceeding standard alarm (residual chlorine, turbidity, TDS), and concentrated water discharge current limiting protection to ensure safe operation of the system.

How is the reverse osmosis skid equipment designed?

The containerized water treatment plant is designed with the core of “adapting to the needs of multiple scenarios. In order to ensure efficient and stable water production, and take into account energy saving and scalability” and designs products in various dimensions.

1. Processing capacity design

The modular container design integrates all components into a single unit. A single unit is designed to handle 3-50 m³/h of water. This precisely meets the basic needs of small and medium-sized water use scenarios, such as small and medium-sized industrial workshops, remote mining areas, emergency water supply points, and rural centralized water supply stations.

We fully integrate the equipment into a standard container, balancing compactness with portability and eliminating the need for additional civil engineering. Furthermore, with customization, we can flexibly expand the maximum system capacity to hundreds of cubic meters per hour, adapting to the dynamic water demands of various scales.

2. Inlet water quality adaptation design

We design different processes for different raw water sources. Such as municipal tap water, surface water, groundwater, and mild industrial wastewater (COD ≤ 50 mg/L, turbidity ≤ 5 NTU), to control the influent TDS to ≤ 5000 mg/L. This prevents impurities and residual chlorine from damaging the reverse osmosis membrane and ensures that the influent meets the core system operating requirements.

3. Design of water quality assurance

We can retain impurities such as inorganic salts, organic matter, colloidal particles, and microorganisms in the water by optimizing the reverse osmosis membrane system design (e.g., selecting high-salinity rejection membrane elements).

Also, by adjusting reverse osmosis system operating parameters (such as operating pressure and recovery rate) to meet the water quality requirements of different scenarios, we can further optimize the purity of the produced water to meet the water quality standards of various applications, such as industrial circulating water, municipal miscellaneous water, and general process water.

4. Operating pressure design

We design the reverse osmosis system’s core pressure to operate at 1.2-1.8 MPa to meet the operational requirements of varying influent water qualities (e.g., high TDS water sources have higher osmotic pressure).

A variable-frequency high-pressure pump is also included to dynamically adjust the pressure based on the actual influent osmotic pressure. Because it can prevent overpressure from damaging the membrane elements or insufficient pressure from reducing water production efficiency.

Why use reverse osmosis skid equipment?

1. Modular design, easy installation

All components are pre-installed and debugged at the factory. On-site, we only need to connect the inlet water, product water, concentrate and power pipelines. The installation period is shortened by 60%-70% compared to a distributed system. The installation period for a single large-scale equipment is ≤15 days.

2. Stable operation

All components of the equipment are from famous brands. Therefore, we can produce products according to the brand required by customers. Therefore, the service life of the equipment can be extended and the operation time can be more stable.

3. Flexible adaptation

It not only supports customization of pre-treatment/post-treatment modules according to influent water quality and produced water requirements. But it can expand processing capacity by connecting multiple skid-mounted units in parallel to meet water needs at different stages.

4. Environmental protection and energy saving

Utilizing variable-frequency high-pressure pumps and low-energy membrane elements, the unit energy consumption per unit of water produced is lower than the industry average.

We can further process bilge water through the brine recovery system. It will increase the recovery rate to 85%-90%, thereby reducing water waste.

Where can we use the reverse osmosis skid machine?

- Boiler feed water treatment in thermal power plants and nuclear power plants

- Petrochemical and coal chemical process water

- Preparation of high-purity water for semiconductor and display production

- Municipal drinking water purification

- Municipal water reuse

- Seawater desalination pretreatment

- Emergency water treatment

If you are interested in this containerized water treatment plant, you can always contact us to get a quote.