In fields such as food processing, pharmaceuticals, and electronics manufacturing, water quality directly impacts product quality. Commercial reverse osmosis equipment, as a highly efficient water purification device, has become an indispensable core component across various industries. Due to its precise impurity filtration capabilities and stable water production efficiency.

What is a commercial reverse osmosis equipment?

It uses reverse osmosis technology as its core principle, applying pressure through a high-pressure pump to force water molecules to pass through a RO membrane with a pore size of only 0.1-1 nanometers. Therefore, it can effectively remove impurities such as heavy metal ions, bacteria, and organic matter from the water. This water treatment equipment can purify water without the need for added chemical reagents.

How does it work?

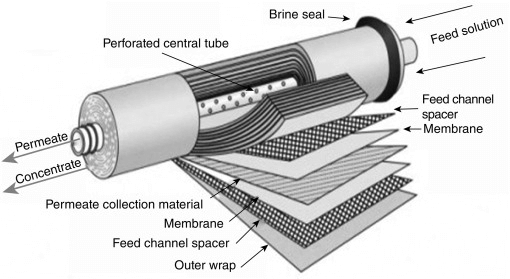

Under natural conditions, water molecules diffuse from low-concentration solutions to high-concentration solutions. RO technology, however, uses a high-pressure pump to apply pressure, forcing water molecules to permeate the semi-permeable membrane in the reverse direction. Thus separate the solute from the solvent. The key to this process lies in the reverse osmosis membrane, whose pore size is only 0.1-1 nanometers, equivalent to one millionth the diameter of a human hair. It can effectively remove impurities. Such as heavy metal ions, bacteria, viruses, and organic matter from the water, with a retention rate of over 99%.

Where can we use commercial reverse osmosis equipment?

In the food and beverage industry, it provides purified water that meets GB 19298 standards for bottled water production. It removes calcium and magnesium ions from water used in beer brewing to prevent affecting the taste of the beer.

In the medical field, its produced water can be used for cleaning medical devices and preparing dialysis water, meeting the stringent requirements of YY 0572-2015. Electronics factories use its high-purity water to prevent short circuits caused by water quality issues during chip manufacturing.

In public service sectors, such as hotels and schools, this equipment provides direct drinking water, replacing traditional bottled water and reducing plastic pollution. The car detailing industry utilizes its mineral-free water to achieve spotless results after vehicle washing.

In industrial wastewater treatment, the equipment can desalinate high-salinity wastewater, enabling water resource recycling.

What does a complete commercial reverse osmosis equipment look like?

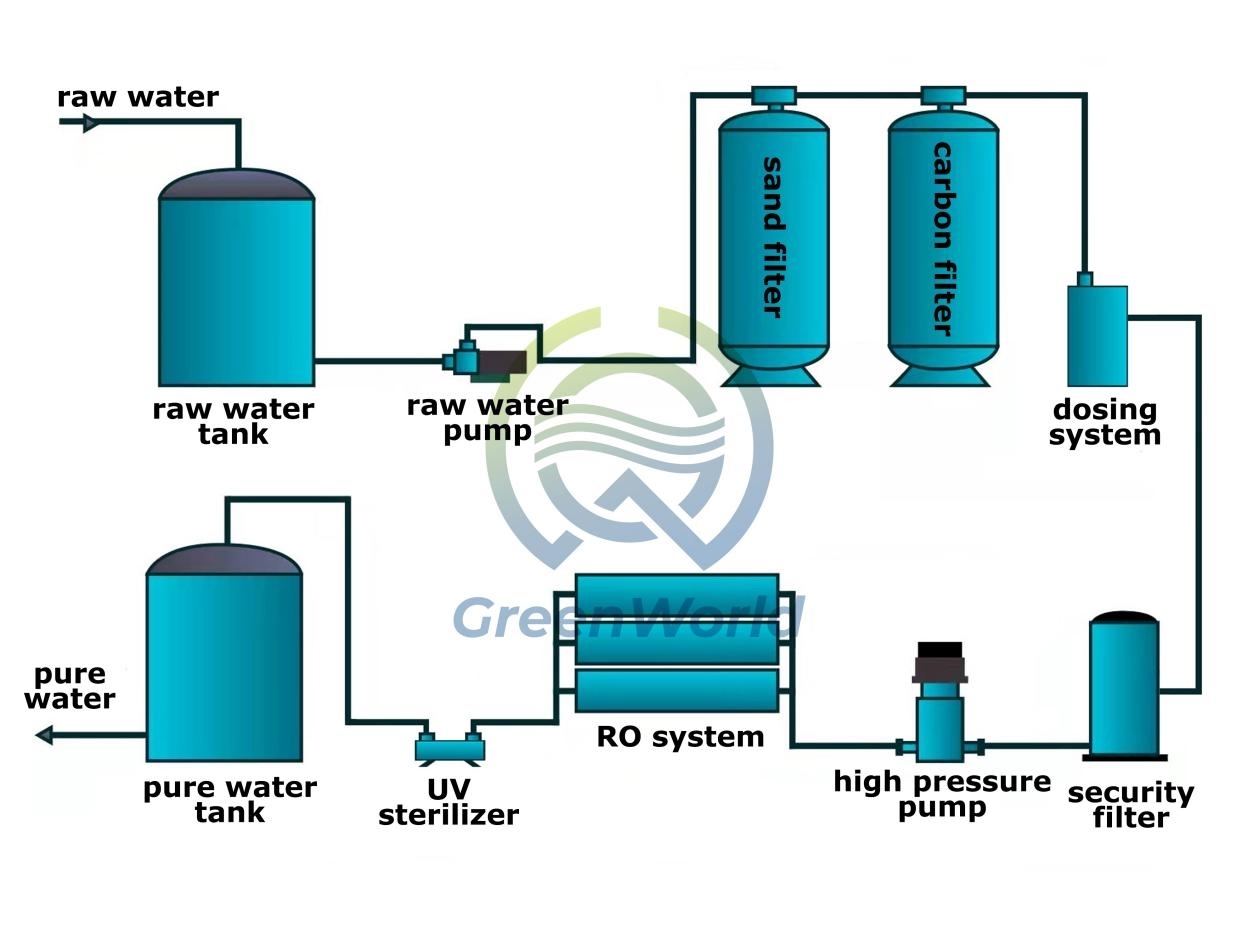

A complete commercial reverse osmosis system consists of a pretreatment unit, a reverse osmosis filtration unit, and a post-treatment unit.

The pretreatment stage uses quartz sand filters and activated carbon filters to remove large particulate impurities. Such as silt and rust, as well as residual chlorine, from the water. This prevents fouling or oxidation of the subsequent membrane modules.

In the core filtration unit, a high-pressure pump pressurizes the pretreated water to 1.0-1.8 MPa, propelling the water through the reverse osmosis membrane modules to complete the purification.

We equip the post-treatment unit with an ultraviolet sterilizer or a pH adjustment device as required to ensure the produced water meets the standards for specific usage scenarios.

How to choose a suitable commercial reverse osmosis system?

Enterprises need to comprehensively consider the raw water quality (such as hardness and TDS value), the required production water volume, and industry standards. For example, when the raw water hardness is high, a softening device is required to prevent membrane scaling. In scenarios with high peak water consumption, we should select equipment with a redundancy flow rate of 1.2-1.5 times. In high-purity water fields such as electronics and medical, we should give priority to thin composite membrane equipment with high desalination rates.

How should we maintain the commercial reverse osmosis machine?

① The pre-filter cartridge needs to be replaced regularly. We recommend replacing PP cotton filters every 1-3 months and activated carbon filters every 6-12 months.

② The RO membrane requires regular chemical cleaning, typically 2-3 times per year, to remove contaminants from the membrane surface.

③ Avoid prolonged equipment downtime. Before shutdown, flush the membrane modules to prevent bacterial growth.

Proper maintenance can extend the membrane module lifespan to 2-3 years, reducing the overall operating cost of the equipment.

Summarize

Commercial RO systems, as core equipment for water purification across various industries, provide safe and reliable water quality assurance and play a vital role in water resource recycling.

In the future, with breakthroughs in membrane material technology and optimization of system integration, their application scenarios will further expand, continuously driving the development of green industry.

If you are interested in this type of equipment, please feel free to contact me for a quote.