Ultrapure water filtration uses a series of physical and chemical methods to remove impurities such as suspended particles, colloids, dissolved ions, organic matter, and microorganisms from water, achieving extremely high purity standards. The resulting pure water meets the requirements of precision manufacturing, high-end chemical engineering, biomedicine, and other applications requiring extremely low impurity levels.

What level of ultrapure water filtration is required?

Resistivity:

Ultrapure water typically requires a resistivity of 18.2 MΩ·cm (25°C). At this temperature, the ion concentration in the water is extremely low. Thus, approach the level of theoretically pure water.

Total Organic Carbon (TOC):

Ultrapure water generally requires a TOC value below 5 ppb (less than 1 ppb in some semiconductor applications).

Particle Content:

We must control the number of particles ≥0.1 μm to less than 10 per milliliter. In order to prevent tiny particles from adhering to the surfaces of precision components and affecting performance.

Microbial Content:

Ultrapure water must be sterile (total colony count <1 CFU/mL).

How does ultrapure water filtration work?

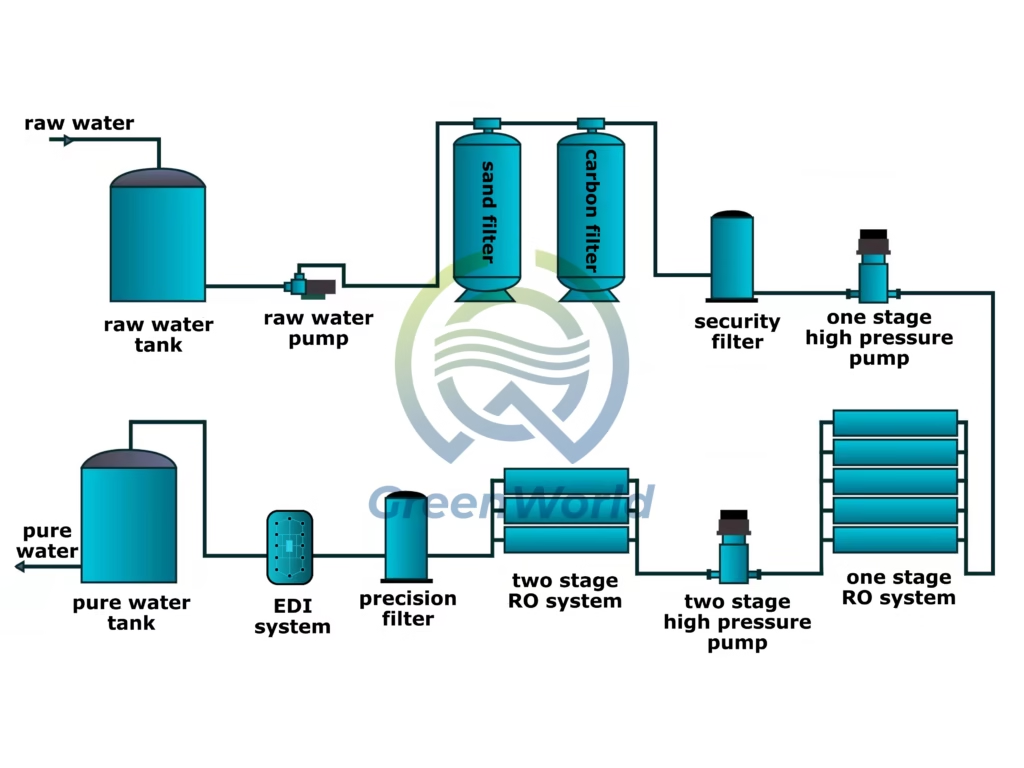

We can divide the purification process of EDI system into five stages. Include pretreatment, primary reverse osmosis treatment, secondary reverse osmosis treatment, deep EDI treatment and terminal water quality assurance.

1. Preprocessing stage

Firstly, the raw water is treated sequentially through a multi-media, activated carbon, and safety filter. Next, a scale inhibitor (hardness <1 mg/L) is added to inhibit scale formation on the RO membrane surface. If the raw water pH is too high (>8.5) or too low (<5.5), we need to adjust the pH to 6.5-7.5 to match the optimal operating pH range of the RO membrane.

This process removes suspended solids, colloids, residual chlorine, hardness (Ca²⁺, Mg²⁺), and some organic matter from the raw water. This prevents subsequent scaling, contamination, or oxidation damage to the RO membrane, ensuring stable operation of the RO system.

2. Primary reverse osmosis treatment stage

Secondly, a high-pressure pump pressurizes the pretreated water to 1.5-2.5 MPa. Using a high-density, fouling-resistant RO membrane, the pressure forces water molecules through the membrane to form “product water.” Dissolved ions and organic matter are retained as concentrated water (20%-30%, which can be discharged or recycled).

The product water enters a buffer tank. Meanwhile, online monitoring of resistivity (100-500 kΩ・cm), conductivity, and a ≥97% desalination rate is required. Abnormal indicators (such as reduced desalination rate due to membrane fouling) trigger an alarm.

This removes 97% of dissolved ions, large organic molecules, and some microorganisms from the pretreated water, significantly reducing the impurity load in the water.

3. Secondary reverse osmosis treatment stage

Thirdly, because the salinity of the primary permeate water has significantly decreased. A secondary high-pressure pump increases the pressure to 1.0-1.8 MPa (lower than

the primary permeate water to prevent membrane damage). We can select a RO membrane with higher desalination efficiency (such as a low-fouling type). The permeate water must have a resistivity of ≥150 kΩ・cm, TOC <50 ppb, and silica <0.1 mg/L (to prevent EDI scaling). If TOC exceeds the specified limits, we can add an 185nm UV oxidation unit before the secondary RO.

The secondary RO concentrate (with a higher salinity than the primary permeate water but lower than the raw water) can be returned to the primary RO feed for re-treatment. Therefore, achieve an overall water recovery rate of 70%-80%.

After this treatment, the treated water fully meets the feed water quality requirements for EDI. The total ion removal rate is ≥99.5% (compared to the raw water), and the permeate water resistivity is 150-1000 kΩ・cm, with TOC <50 ppb.

4. Deep EDI desalination

After secondary reverse osmosis treatment, water passes through an EDI module (containing an ion-binding membrane, resin, and electrodes), and we pass a DC current (1-5 A) through it. Ions migrate to the concentrate chamber for discharge. Next, the freshwater flow rate is controlled (1-3 L/min per module) and the resistivity of the product water is monitored.

This treatment achieves the core specifications for industrial ultrapure water. Such as those required by the semiconductor and biopharmaceutical industries. Ion removal efficiency ≥99.9%, product water resistivity 15-18 MΩ cm, TOC <10 ppb, and silica content <0.01 mg/L.

5. Ensure terminal water quality

At the terminal, we need to use a 0.02-0.1μm microfiltration membrane or ultrafiltration membrane to intercept resin fragments and microorganisms that may fall off the EDI module.

We need to tailor ultraviolet (UV) sterilization to the application. For example, in the biopharmaceutical and food industries, 254nm wavelength UV lamps are used to destroy microbial DNA. In some applications, 185nm UV can be added to reduce TOC to <5 ppb. Ultrapure water storage tanks in the semiconductor industry can be filled with high-purity nitrogen with a purity of ≥99.999% to isolate the air.

Finally, we circulate the ultrapure water through 316L stainless steel pipes. So as to prevent stagnant water from breeding microorganisms and reduce impurity adsorption.

This treatment meets the extreme water requirements of high-end industrial applications. The terminal product water has a resistivity of 18.2 MΩ・cm (25°C), TOC <5 ppb, a particle content of ≥0.1 μm <1 particle/mL, and is sterile.

Where can we use ultrapure water filtration?

①Semiconductor and electronics industry

During semiconductor chip manufacturing processes (such as wafer cleaning, photolithography, and etching), ions, particles, and organic matter in the water can cause chip circuit shorts and distort photolithographic patterns.

Our ultrapure water filtration system uses a combined “RO + EDI + UV + terminal ultrafiltration” process to provide stable, high-purity water for chip production.

![]()

②Biopharmaceutical Industry

Ultrapure water used in pharmaceutical production and medical device cleaning must meet Good Manufacturing Practice (GMP) requirements: sterility, pyrogen-free (endotoxins < 0.25 EU/mL), and TOC < 5 ppb.

The filtration system utilizes a “UF + RO + EDI + terminal sterilizing filtration” process to remove microorganisms and pyrogens, preventing pharmaceutical contamination.

③Power Industry

Ionic impurities in boiler water used in thermal or nuclear power plants can cause scale to form on the boiler walls, leading to reduced thermal efficiency, pipe corrosion, and even explosions.

Ultrapure water filtration uses an “RO + ion exchange” process to reduce the resistivity of boiler feed water to 5-10 MΩ・cm and a hardness (measured as CaCO₃) of less than 0.1 mg/L, reducing scale formation and extending equipment life.

④New Energy Industry

In the production of lithium battery cathode materials and photovoltaic silicon wafers, metal ions (such as Na⁺ and K⁺) in water can affect battery capacity and photovoltaic module conversion efficiency.

Ultrapure water filtration systems must control metal ion content to less than 0.1 ppb. Using a “RO+EDI+chelating resin” process, they provide low-impurity water for the synthesis of new energy materials.

What are the problems with using ultrapure water equipment?

High Energy Consumption

Core technologies such as reverse osmosis and EDI consume significant amounts of electricity (e.g., RO requires an operating pressure of 1-4 MPa). Some traditional ion exchange processes require frequent use of acid and alkali regeneration agents, resulting in high operating costs and significant environmental pressures.

Poor Adaptability to Complex Water Quality

Some industrial raw water (e.g., high-salt wastewater and wastewater containing heavy metals) has complex composition, making filtration systems susceptible to membrane fouling and resin poisoning, requiring frequent replacement of consumables.

What upgrades are there in ultrapure water filtration?

Energy-saving technology upgrades

Using low-energy RO membranes and new EDI modules (reducing energy consumption by over 30%), combined with waste heat recovery systems, we reduce energy consumption.

Integrated equipment

Targeting the needs of small and medium-sized customers, we use modular ultrapure water equipment (such as “pretreatment + RO + EDI” integrated units) to shorten installation cycles and reduce operational complexity.

Conclusion

Ultrapure water filtration utilizes a tiered purification process combining two-stage reverse osmosis and EDI to transform ordinary raw water into ultrapure water of the highest purity. This provides a core water guarantee for the high-quality development of key industries such as semiconductors, biopharmaceuticals, and new energy.

Currently, faced with challenges such as high energy consumption and poor adaptability to complex water quality. The water treatment industry is innovating and upgrading to more efficient and environmentally friendly solutions. Help the global manufacturing industry transition towards precision and low-carbon production.

If you have other EDI 供水系統 questions, you can always consult us.