Recently, we successfully shipped an ultrapure water filtration system. And it will arrive in Phuket, a famous tourist destination in Thailand. This equipment will be used in the medical, electronics manufacturing and tourism supporting industries.

Why use ultrapure water filtration system?

As a tropical island, Phuket boasts abundant marine resources, but freshwater resources are relatively scarce. Furthermore, factors such as surging water demand during peak tourist season and stringent water standards for certain industries place even higher demands on the supply of high-quality pure water.

We custom-designed the 1000L/hour ultrapure water filtration system shipped this time. It based on Phuket’s climate, raw water quality data, and actual local customer applications. Its energy-saving design reduces energy consumption by approximately 15% compared to traditional pure water equipment.

How does ultrapure water filtration system?

The EDI system utilizes a multi-stage purification process, including a pretreatment system, two-stage reverse osmosis, and electrodeionization. It not only effectively removes sediment, colloids, microorganisms, heavy metal ions, and dissolved organic matter from raw water. But also increases the water resistivity to over 18.2 MΩ·cm. This equipment fully meets the extremely high water quality standards required for medical equipment cleaning, electronic component production cooling, and high-end hotel guest room water. Furthermore, considering Phuket’s high temperature and high humidity, we construct the entire system using corrosion-resistant 304 stainless steel. And we treat its core components to resist moisture and oxidation.

What is the workflow of the EDI system?

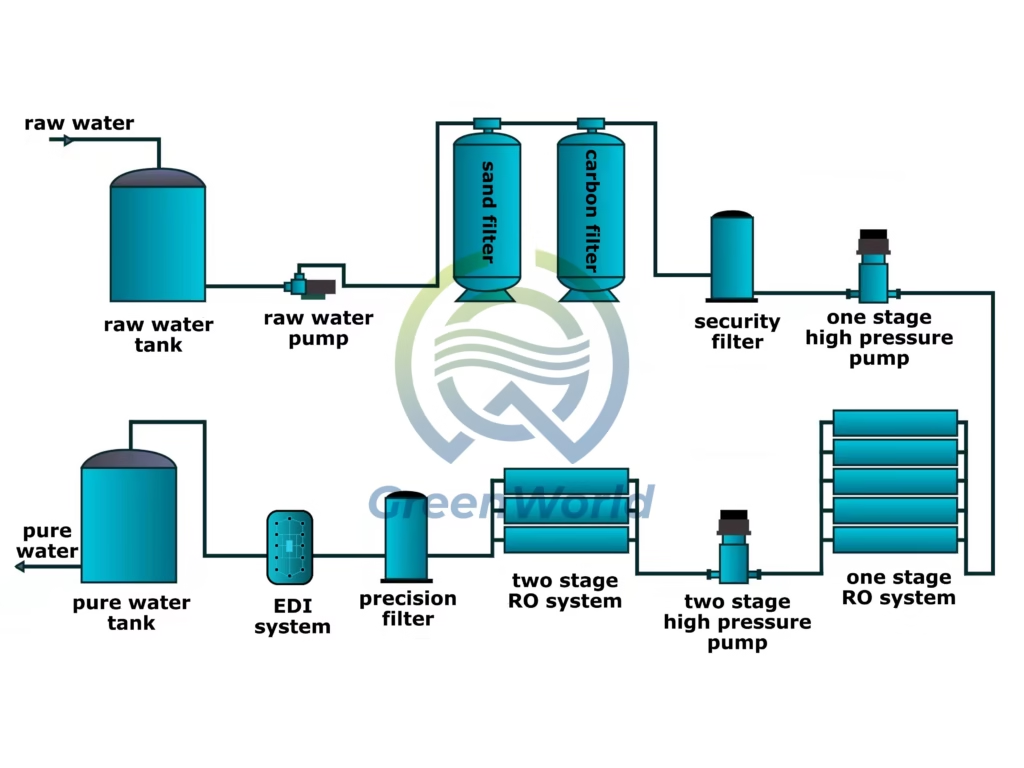

We can divide our EDI equipment workflow into four steps.

Firstly, the raw water pretreatment stage

A multi-media filter removes large particles of impurities such as silt and rust from the raw water. An activated carbon filter then absorbs residual chlorine and organic matter. Finally, a safety filter removes fine suspended solids to prevent subsequent membrane element clogging.

Secondly, primary reverse osmosis treatment

The pretreated water enters the primary reverse osmosis membrane. Under high pressure, water molecules pass through the membrane and become primarily pure water, while the membrane retains and discharges contaminants such as salts and heavy metal ions. This initial improvement in water purity results in the removal of over 97% of dissolved solids.

Thirdly, secondary reverse osmosis treatment

The primary reverse osmosis product water enters the secondary reverse osmosis membrane, where we further filter it to remove trace salts, organic matter, and other impurities—this raises the water resistivity to 1-10 MΩ·cm. This treatment meets the basic pure water requirements of most industrial processes while reducing the load on subsequent EDI processing.

Finally, the EDI deep desalination stage

The secondary reverse osmosis product water enters the EDI module, where an electric field causes the remaining ions in the water to migrate to the corresponding electrodes and removes them. Without the need for regeneration chemicals, we can increase the resistivity of water to over 18.2MΩ・cm, and ultimately produce ultrapure water.

How to transport ultrapurewater filtration system?

From the moment the EDI system leaves the factory until it arrives at the customer’s site in Phuket, we use shock-resistant packaging, including wooden crates, bubble wrap, and stretch film. The crates are custom-sized, and the equipment is secured to a dedicated transport vehicle during transportation to prevent damage to components caused by bumps during transit.

We fully document the entire process, from order placement to delivery, which eliminates the need to worry about delayed delivery. After customs clearance at the port, the equipment is shipped directly to Thailand by ship, with merchandisers tracking the shipment’s progress in real time. Upon arrival at the Thai port, we will transport it directly to the installation site in Phuket by road. The entire transportation process is efficient and safe, ensuring on-time delivery of the equipment.

Which field uses this device?

- In the medical field, high-quality ultrapure water is used for cleaning and disinfecting hospital operating room instruments, as well as for laboratory testing and analysis.

- In the electronics manufacturing sector, this equipment will provide companies with a stable supply of pure water, breaking the water quality bottleneck in the electronics industry.

- Furthermore, in tourism-related facilities, deep purification improves the taste and cleanliness of water, providing tourists with a superior living experience.

Summarize

This equipment has solved water treatment challenges in Phuket, Thailand, for the medical, electronics manufacturing, and tourism industries. It represents a valuable example of cooperation between China and Thailand in environmental protection technology and industry.

In the future, with the continuous innovation and upgrading of our EDI technology, more high-quality water treatment equipment will enter the international market. This will not only advance ultrapure water filtration system, but also reverse osmosis, desalination, and ultrafiltration equipment. If you require such equipment, please feel free to contact us.