Ultrafiltration system, a pressure-driven membrane separation process, effectively captures suspended solids, colloids, microorganisms, and some macromolecular organic matter in water. Therefore, it plays a key role in municipal water supply, industrial wastewater treatment, water resource recycling, and household water purification.

Central European countries, due to their stringent regulations and standards (DWD, WFD), leading technological R&D capabilities, and emphasis on sustainable development, have become core regions for the application and innovation of ultrafiltration systems.

What is the role of the ultrafiltration system?

1. As the core filtration unit

By 2025, approximately 45% of new municipal water plants in Europe will use ultrafiltration as a core filtration unit. Because, ultrafiltration system offers significant advantages over traditional sand filtration processes:

After completing an ultrafiltration retrofit in 2019. The Weissensee Waterworks in Berlin, Germany, has maintained a stable water turbidity level below 0.1 NTU. Not only achieve a 100% removal rate for Cryptosporidium and Giardia. But it has reduced chlorine disinfectant usage by approximately 30%, avoiding the formation of disinfection byproducts (such as trihalomethanes).

The Marne-la-Vallée Waterworks near Paris, France, utilizes a combined ultrafiltration + ultraviolet disinfection process. In other words, it eliminates the need for chemical additives and ensuring a “chemical-free” drinking water supply. It treats 120 million cubic meters of water annually, serving over 500,000 residents.

2. Industrial pure water pretreatment

Because high value-added industries such as food and beverage, pharmaceuticals, and electronics have extremely high requirements for the purity of production water. Ultrafiltration machine has become a pretreatment method for process water.

- Food and Beverage Wastewater Treatment

Heineken’s Rotterdam plant in the Netherlands uses ultrafiltration to treat brewing wastewater. The recovered water can be reused for raw material cleaning, actually achieving a water reuse rate of 75%, reducing industrial water consumption by approximately 120,000 cubic meters annually.

- Pharmaceutical production wastewater treatment

In fact, Roche Pharmaceuticals’ Basel production base in Switzerland uses a dual-membrane process of “ultrafiltration + reverse osmosis” to treat production wastewater to the “water for injection” level that meets pharmacopoeia standards. This not only reduces the cost of purchasing fresh water, but also reduces the discharge of hazardous wastewater.

- For household water purification

In rural areas with poor water quality, small-scale ultrafiltration water purification equipment has become a household necessity. For example:

In the Scandinavian region of northern Sweden, where groundwater contains high levels of colloids and humus, approximately 30% of households have installed small-scale ultrafiltration water purifiers. These just require tap water pressure, having filter cartridges with a lifespan of one to two years, and produce drinkable water.

What does our ultrafiltration system look like?

XinJieYuan has long been a global leader in the research and development of ultrafiltration technology. Because, its core innovations focuses on “membrane materials, integration, improved stability, and application scenarios.”

1. Anti-fouling and long-life membrane materials

The “anti-fouling PVDF ultrafiltration membrane” we use introduces hydrophilic groups on the membrane surface, reducing the contact angle from 85° to 35°. This reduces the adsorption of organic matter and colloids on the membrane surface, extending the membrane cleaning cycle from the traditional 7 days to 30 days, and achieving a service life of 5-7 years (compared to 3-4 years for traditional membranes).

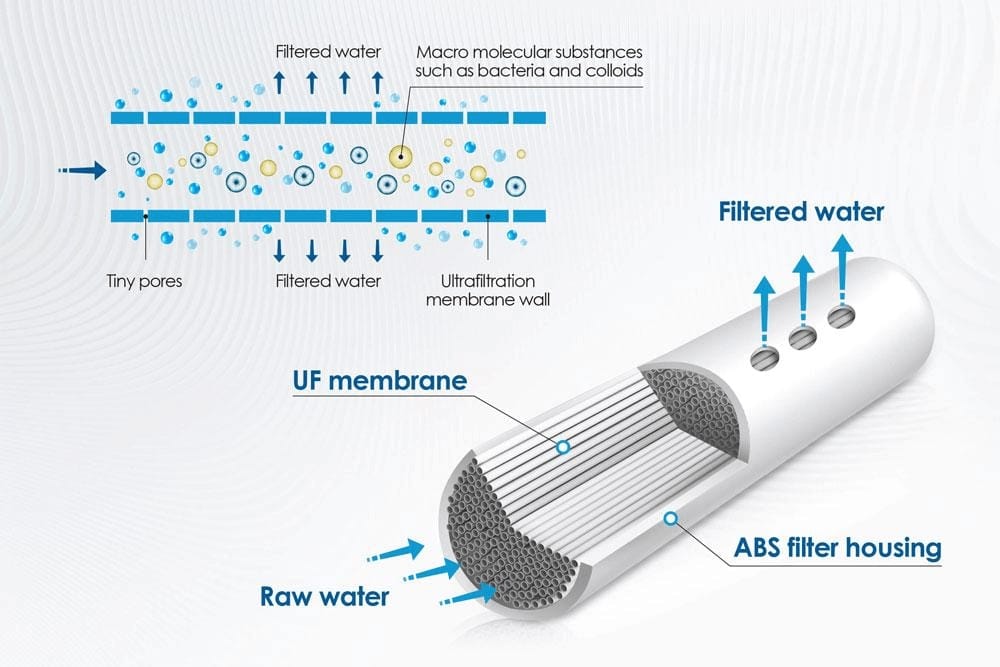

We can also use another membrane material to manufacture equipment: “hollow fiber ultrafiltration membrane.” This membrane uses an “external pressure” design, with water flowing from the outside to the inside of the membrane. This reduces the chances of contaminants clogging the membrane pores. And improve backwash efficiency by 40%, and reduce energy consumption by approximately 25%.

2. Modular system

The small-scale ultrafiltration equipment we have launched has a single module processing capacity of up to 5-10 cubic meters per hour. It can be flexibly combined according to needs and is suitable for decentralized treatment in small rural water plants or industrial workshops.

3. Save energy

We have optimized the ultrafiltration process. By optimizing the water pump pressure and backwashing strategy, the energy consumption per unit water volume has been reduced to 0.2-0.3 kWh/m³, which is only 60% of that of traditional ultrafiltration systems.

4. There are various application examples

During the 2025 drought in southern Spain, we deployed 10 mobile ultrafiltration systems to treat groundwater or river water. And we have provided 5,000 cubic meters of water daily and solved the drinking water problem for approximately 20,000 residents.

In the Andalusian Agricultural Region in southeastern Spain, we used an ultrafiltration + drip irrigation system to repurpose treated agricultural wastewater for olive grove irrigation, increasing water efficiency by 60% and reducing water consumption per acre of olive grove by 40%.

What are the directions for improving the ultrafiltration system?

Although ultrafiltration systems are relatively mature in Europe, their initial investment costs are 2-3 times higher than traditional sand-based systems, and membrane replacement costs are relatively high. Therefore, various improvements are needed.

In the future, we will develop nanocomposite ultrafiltration membranes (such as graphene-modified PVDF membranes). In order to further enhance filtration accuracy and anti-fouling capabilities, with the goal of extending membrane lifespan to 10 years. We will also develop solar-powered ultrafiltration systems suitable for remote rural areas or islands. Currently, Germany is piloting such a system on the Baltic Sea island of Rügen, treating 100 cubic meters of water daily.

Ultrafiltration systems are no longer simply water treatment technologies; they are core tools for achieving clean water security and a circular economy. From municipal applications to household terminals, our diverse practices have provided a valuable model for the development of ultrafiltration technology worldwide.

If you require inquiries about ultrafiltration system solutions, please feel free to contact us. We will tailor a solution to your specific needs as soon as possible.

문의하기

Name: Cliff Mok

Mobile phone: +86 17817887719