In the laboratory ultrapure water preparation system, the EDI water system, with its core advantage of “no need for chemical regeneration and continuous and stable water production”, has become a key purification unit connecting “primary pure water” and “high-purity ultrapure water” so far.

EDI ultrapure water system actually is a novel purification device. It deeply integrates electrodialysis and ion exchange technologies. And Its core function is to deeply purify “primary pure water” after reverse osmosis (RO) pretreatment. So it can remove residual trace ions, some organic matter, and colloids. The resulting ultrapure water has a resistivity of 15-18.2 MΩ·cm (at 25°C), without the need for acid or alkali regeneration agents.

In the laboratory ultrapure water production process, EDI ultrapure water system typically plays a key role in the “pretreatment” phase. It involves primary purification with RO (removal of oxygen) purification, advanced purification with EDI, and final purification (UV sterilization/ultrafiltration).

The upstream RO system not only can remove over 97% of ions and contaminants, but reducing the load on the EDI system electrodeionization equipment.

The downstream final purification unit can further reduce total organic carbon (TOC) and microbial content, meeting the customized needs of different experimental scenarios.

How does ultrapure water system work?

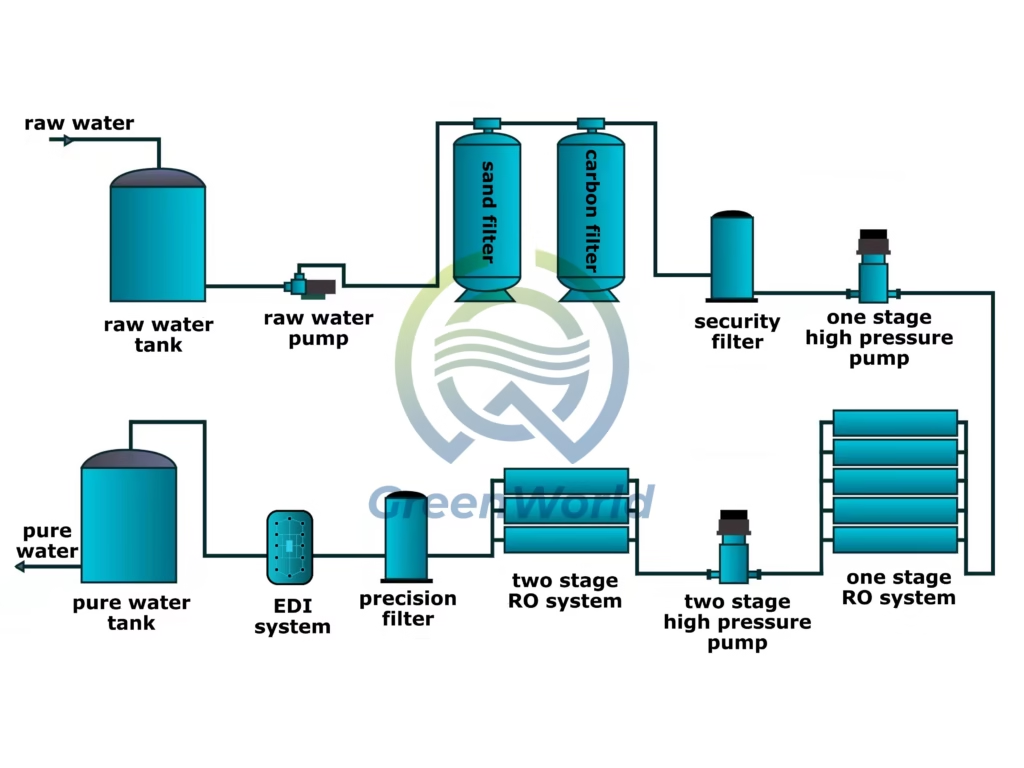

In laboratory high-purity ultrapure water preparation systems, the “two-stage reverse osmosis (RO) + EDI” combination is one of the current mainstream solutions. Two-stage RO further reduces the impurity concentration of raw water through two membrane filtrations, providing qualified feed water for EDI system. Then EDI achieves deep deionization on this basis, ultimately producing ultrapure water that meets scientific research needs.

1. Raw water pretreatment

Firstly, remove impurities such as suspended matter, residual chlorine, calcium and magnesium ions (scale) in raw water to avoid damage to subsequent RO membranes and extend equipment life.

2. Primary reverse osmosis purification

Secondly, through the “selective permeability” characteristics of the semi-permeable membrane, 90%-95% of the ions, organic matter and microorganisms in the raw water are removed, completing the transformation of “raw water → primary pure water”.

3. Secondary reverse osmosis deep filtration reduces EDI inlet water load

Thirdly, the primary RO product water is filtered again to further remove residual ions and organic matter to ensure that it meets the strict water inlet requirements of the EDI equipment.

4. EDI deep purification

Besides, removes trace ions from secondary RO product water and improves the water quality to ultrapure water level.

5. Disinfection and sterilization

Finally, based on specific experimental requirements (such as sterility, endotoxin-free, and low TOC), we further optimize EDI produced water to ensure that the water quality fully matches the experimental requirements.

Why is ultrapure water system the preferred choice?

Compared to traditional purification technologies (such as mixed-bed ion exchange and reverse osmosis alone). Two-stage reverse osmosis + EDI equipment offers significant advantages in terms of stability, environmental friendliness, and operational and maintenance costs. These advantages can be summarized in four key aspects:

1. Stable water quality

First, the treatment process can stably maintain the resistivity of produced water at 15-18.2 MΩ・cm (25°C), reduce the total organic carbon (TOC) to 5-20 μg/L, and achieve an ion removal rate as high as over 99.9%.

2. No need for acid-base regeneration

Second, the EDI system does not require any chemical agents to be added throughout the process, is driven only by electricity, and does not cause wastewater pollution.

3. Continuous and stable water production

Thirdly, EDI system can achieve 7×20 hours of continuous water production without the need for frequent shutdown and regeneration like traditional mixed beds.

4. Real-time monitoring

Last, the PLC control system can monitor the resistivity, flow rate, temperature and other parameters of produced water in real time.

How to choose ultrapure water system?

When selecting laboratory ultrapure water EDI system, consider factors such as the laboratory’s water needs, raw water conditions, and experiment type, and focus on the following key technical parameters:

1. Matching Water Accuracy

Production Water Resistivity: A core indicator, selected based on experimental requirements.

Production Water Output: We should determine this based on the laboratory’s average daily water consumption.

TOC Removal Rate: Typically ≥90%, ensuring TOC in production water ≤20 μg/L.

Influent Water Requirements: EDI equipment has high requirements for influent water quality and requires a qualified pretreatment and RO system.

2. Equipment Configuration Parameters

Membrane and Resin Quality: Imported or reputable ion exchange membranes (such as DuPont and Suez) are preferred.

Control System: We recommend a PLC control system with a touchscreen for real-time display of production water parameters.

Material Compatibility: Equipment components contacting water (such as piping and tanks) must be made of 316L stainless steel.

As a deep purification technology featuring “no chemical regeneration and high stability”. Laboratory ultrapure water EDI equipment has evolved from an “optional” option to a “standard feature” in high-end research laboratories.

Going forward, EDI system will further adapt to the laboratory’s trend toward miniaturization, customization, and low carbonization. And it will become a crucial support for scientific research innovation.